Microstructure and Mechanical Properties of Mg-Gd-Er-Zn Wrought Magnesium Alloy Containing RE

-

摘要:

为研究Mg-Gd-Er-Zn稀土变形镁合金微观组织与力学性能,通过金属模铸造、固溶处理、热挤压和时效处理工艺过程,制备了Mg-Gd-Er-Zn稀土变形镁合金,并利用金相显微镜(optical microscopy,OM)、X射线衍射仪(X-ray diffraction,XRD)、扫描电镜(scanning electron microscopy,SEM)及透射电镜(transmission electron microscopy,TEM)等手段进行表征.结果表明:Mg-Gd-Er-Zn合金的铸态组织主要由α-Mg基体和沿晶界分布的(Mg,Zn)3Gd第2相组成,固溶后生成层片状的长周期堆垛有序(long period stacking ordered,LPSO)结构;经过热挤压变形,合金的晶粒得到显著细化;时效处理过程中,合金中析出纳米级尺寸的β'相.最终时效态合金的室温抗拉强度、屈服强度和伸长率可分别达397.5 MPa、359.0 MPa和6.0%.

-

关键词:

- Mg-Gd-Er-Zn /

- 长周期堆垛有序(LPSO) /

- 微观组织 /

- 力学性能 /

- 强韧化机制

Abstract:In order to research the microstructures and mechanical properties of Mg-Gd-Er-Zn wrought magnesium alloy under different states. Mg-Gd-Gd-Zn alloy was prepared by conventional metal mold casting, solution treatment, subsequently hot extrusion and ageing treatment, and was studied by using optical microscopy (OM), X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that the as-cast microstructures of Mg-Gd-Er-Zn alloy consists of α-Mg matrix and second-phase (Mg, Zn)3Gd phase which distributes around α-Mg matrix. After solution treatment, the lamellar long period stacking ordered (LPSO) structure appeared. During hot extrusion, the grain of this alloy can be refined dramatically. And subsequently aged, the nano β' phases were precipitated. Finally, the tensile strength, yield strength and elongation of the aged alloys at room condition reach 397.5 MPa, 359.0 MPa and 6.0%, respectively.

-

镁合金是目前最轻的实用化金属结构材料,具有比强度和比刚度高、电磁屏蔽能力强、减震性能好等一系列优点,是制造机器人、汽车、电子产品等零部件的理想材料之一[1-5].

目前,制约镁合金大规模应用的瓶颈主要是其强度低、室温塑性差和易腐蚀等[6-7].尤其镁合金同钢铁、铝合金材料相比,其绝对强度较低.研究表明,稀土元素的加入可以提高镁合金的室温和高温性能,降低腐蚀速率及改善其塑性成形能力[8].近年来,Mg-Gd系、Mg-Y系、Mg-Zn-Gd系和Mg-Gd-Y系合金由于具有良好的室温力学性能引起研究者的广泛关注. Gao等[9]研究了经T6时效处理后的Mg-15Gd-4Y-0.5Zr合金,其抗拉强度为276.9 MPa;彭卓凯等[10]研究了Mn和Zr对Mg-Gd-Y合金组织与力学性能的影响,结果发现T5态Mg-9Gd-4Y-0.6Zr合金具有较高的强度,其抗拉强度可达370 MPa.

稀土镁合金不仅有着优异的时效沉淀强化作用,而且在Mg-RE系合金中加入少量的Zn可形成长周期堆垛有序(long period stacking ordered,LPSO)结构[11-12].含有长周期有序堆垛相的合金,特别是Mg-RE-Zn合金,在经塑性变形后,能够使长周期结构在合金中均匀分布,同时细化基体晶粒,从而极大地提高合金的强度和塑性,展示出极其优异的室温和高温力学性能[13-16].

本研究以高性能镁合金材料需求为导向,开发了新型Mg-Gd-Er-Zn高强稀土变形镁合金材料,并对合金的热处理和热挤压工艺、微观组织、力学性能及强化机制等展开研究.

1. 实验方法

本文研究的合金铸锭采用常规熔炼铸造工艺制备.合金原料采用商用纯镁(w=99.99%)、纯锌(w=99.99%)、Mg-Gd(w=30%)中间合金、Mg-Er(w=30%)中间合金、Mg-Zr(w=30%)中间合金,上述合金锭打磨去除掉表面氧化皮后,在配有SF6+N2保护气氛的井式坩埚电阻炉中完成熔炼.首先,将坩埚在200 ℃预热烘干后升温至700 ℃,在纯镁熔化后顺序加入Mg-Gd、Mg-Er中间合金;其次,将合金熔体升温至720 ℃并保温15 min,然后加入Zn合金和Mg-Zr中间合金,搅拌均匀化和保温;最后,将合金熔体温度调整至680 ℃并浇铸于预热至200 ℃的金属模中,获得Mg-Gd-Er-Zn稀土镁合金铸锭.将获得的镁合金铸锭依次经固溶、热挤压和时效工艺后,获得高性能Mg-Gd-Er-Zn变形镁合金棒材.

利用Magix-PW2403型X射线荧光光谱仪分析合金成分,结果为Mg97.69Gd1.60Er0.27Zn0.20Zr0.25.利用D/MAC-3C型旋转阳极X射线衍射仪,分析不同状态下合金的相组成.利用Netzsch STC449C热分析仪研究铸态合金熔化过程中的吸热、放热特性,以合金不发生过烧和保证第2相充分固溶为前提,确定合金的固溶温度和时间.利用Y32型100 t液压机对固溶态镁合金坯料进行热挤压,热挤压温度为400 ℃,挤压比为10:1,对热挤压棒材进行水淬处理.挤压态镁合金棒材的时效温度设定为225 ℃,其时效时间通过时效硬化曲线确定.时效态合金样品的显微硬度在HXD-1000显微硬度测试仪上进行测试,每个试样至少测试10个点,并取其平均值作为该状态样品的硬度.

铸态、固溶态、挤压态和时效态镁合金试样经磨制、抛光和5%硝酸酒精腐蚀后,利用Zeiss Axio Imager A2m光学显微镜、HITACHI S3400N型扫描电镜及能谱分析仪(energy-dispersive spectrometry,EDS)附件观察其显微组织,并分析其晶粒尺寸及第2相尺寸、形貌、成分等.利用JEM-2100型透射电镜分析合金时效态的高分辨显微形貌及析出相.利用UTM-4304型万能材料试验机测试合金的力学性能,力学拉伸试样的直径为5 mm,标距为25 mm,试样的拉伸速度为1 mm/min.

2. 实验结果及讨论

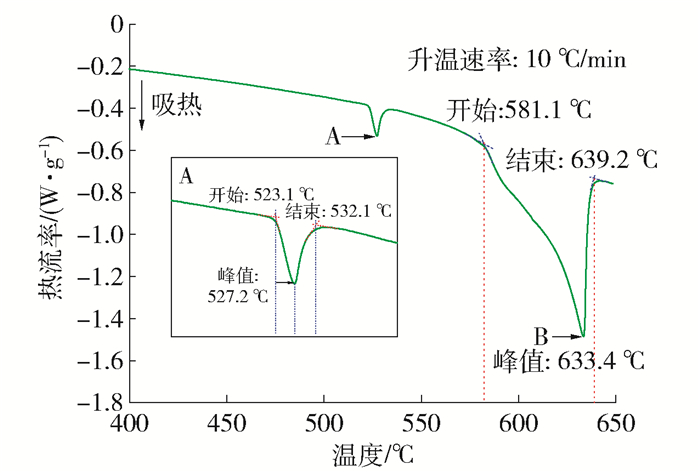

2.1 铸态合金的热分析

图 1为铸态合金的热分析曲线,根据差热分析(differential scanning calorimetry,DSC)曲线可以发现合金在升温过程中出现了2个吸热峰,如图 1中A、B所示.其中第1个吸热峰A为(Mg, Zn)3Gd的熔化吸热峰,其起点温度为523.1 ℃、终点温度为532.1 ℃、峰值温度为527.2 ℃;第2个吸热峰B为α-Mg的熔化吸热峰,其起点温度为581.1 ℃、终点温度为639.2 ℃、峰值为633.4 ℃.综合上述分析结果,为避免合金中第2相过烧,将合金的固溶温度定为500 ℃,该温度略低于第2相的分解温度,从而保证了整个热处理过程处于固态相变范围.为使合金中的第2相得到充分溶解,设定合金的固溶时间为12 h.

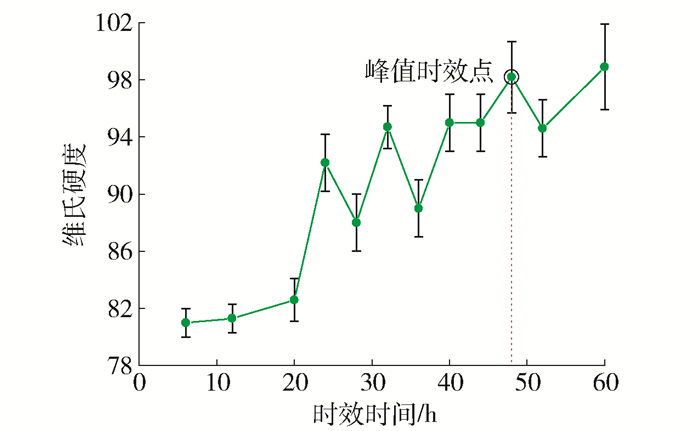

2.2 合金的时效硬化特性

热挤压态合金在225 ℃的时效硬化曲线如图 2所示.从图 2可看出,所研究合金在225 ℃时效温度下有明显的时效硬化效果,其硬度值随时效时间的延长而不断增加,当时效时间达到48 h时,合金出现了一个时效硬化峰值,再延长时效时间,合金的硬度并未有显著增加.因此,在后续的时效工艺中,设定峰时效处理时间为48 h.

2.3 合金的显微组织

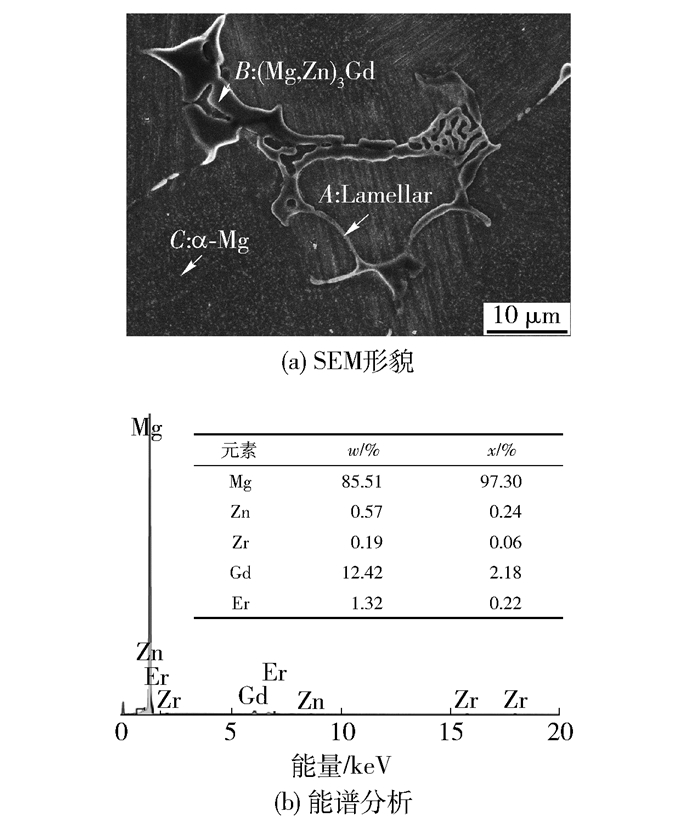

图 3(a)为铸态合金的SEM形貌,B点所示为(Mg, Zn)3Gd相,主要沿晶界析出,呈网格状分布,与α-Mg相形成共晶组织[17].同时,可以观察到(Mg, Zn)3Gd相周围存在大量的浅灰色絮状结构,该絮状结构由晶界向晶内延伸,平行分布于基体中与基体没有清晰的界面.对图 3(a)中A点所示层片状结构进行成分分析,其结果如图 3(b)所示,(Mg, Zn)与(Gd, Er)的原子比约为98:2,根据相关研究结果,该组织由2H-Mg与14H-LPSO结构组成[18-19].

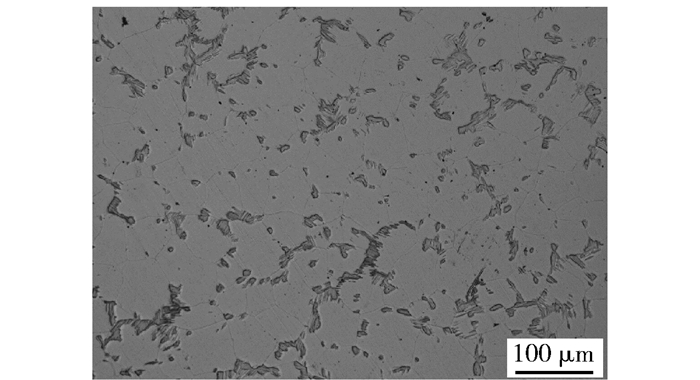

为了消除铸态合金中粗大的(Mg, Zn)3Gd相以及成分偏析,铸态合金经500 ℃和12 h固溶处理后,显微组织形貌如图 4所示.分析表明,固溶之后的晶粒平均尺寸为26 μm,铸态合金中呈网格状分布的(Mg, Zn)3Gd相基本消失,但在固溶态晶界附近出现大量片层状结构,这些片层状结构为14H-LPSO结构,该结构在铸态中出现[20].

研究指出,14H-LPSO结构形成的方式有2种:第1种为合金在凝固冷却过程中Mg、Gd和Zn原子发生调幅分解,导致晶格点阵发生错排,进而形成堆垛结构,当动力学和热力学条件满足时,在过饱和固溶体中形成层片状结构,即14H-LPSO;第2种为固溶过程中(Mg, Zn)3Gd相发生固态相变转变成LPSO结构.在晶内和晶界形成的14H-LPSO具有优异的高热稳定性和塑性变形能力,有利于提高合金的强度和塑性甚至超塑性[21].

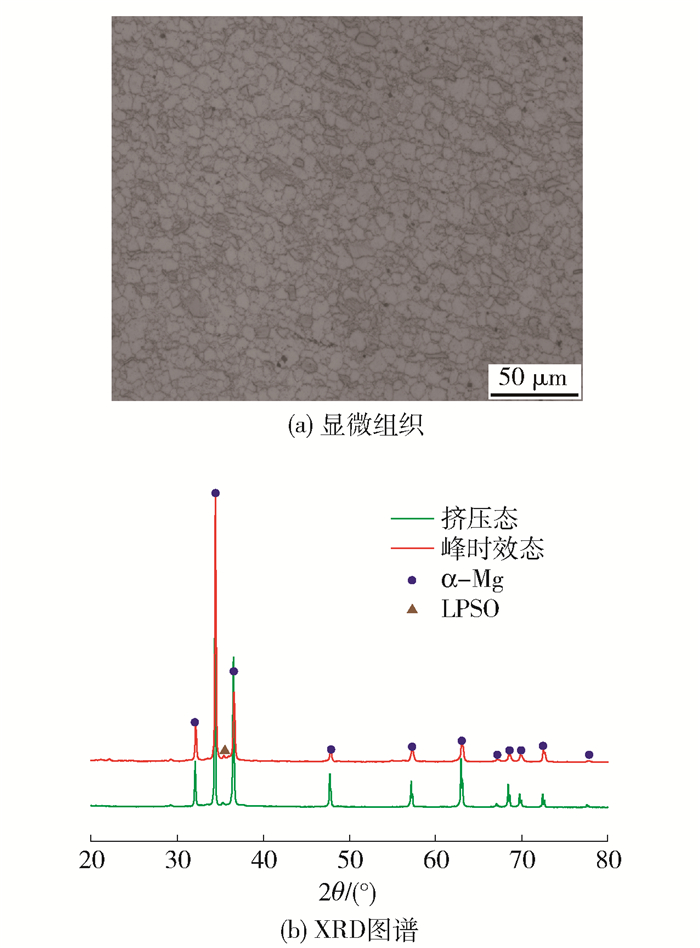

图 5(a)为经固溶、热挤压,并进行225 ℃×48 h峰时效处理的合金光学显微组织.从图 5(a)可以看出,最终获得的高强镁合金晶粒尺寸非常细小,平均晶粒尺寸为10 μm,与固溶态合金的晶粒尺寸相比较明显发生细化,挤压后的晶粒近似等轴状,表明在前序的热挤压中合金发生了动态再结晶.合金在热挤压变形过程中,层片状LPSO发生塑性变形,均匀分布于基体中,位错运动受到LPSO颗粒的钉扎而产生塞积,使合金产生形变强化.结合XRD衍射图谱可知,合金固溶处理后得到的LPSO结构是一个热稳相,在合金经过挤压和时效工艺后依然存在,但是热挤压态与峰时效态合金的相并没有发生明显变化,这主要是由于时效析出相较少,导致XRD图谱中衍射峰不明显.

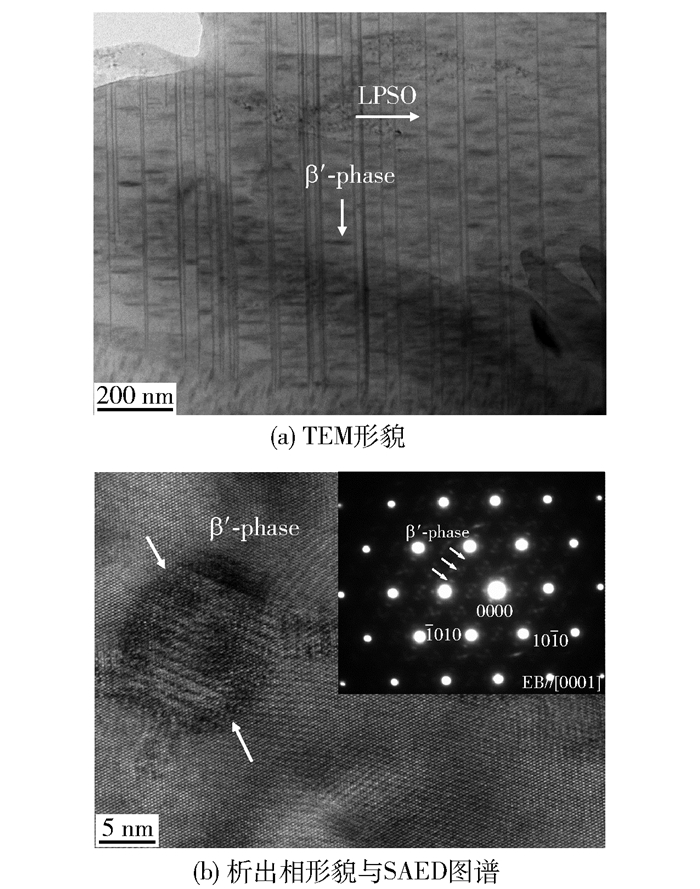

图 6为合金在峰时效后的TEM形貌.从图 6(a)可以发现,峰时效后镁合金基体中LPSO结构与β′相的共存.如前所述,LPSO结构是一种热稳态相,在后续的热挤压、时效等工艺中可稳定存在.因此,合金在发生动态再结晶的热挤压过程中,LPSO相可以通过钉扎晶界产生显著的细晶强化作用,而且在合金时效过程中LPSO相也将阻碍β′相的粗化,有效提高β′相的时效强化效果[22].

合金峰时效析出相的高分辨TEM形貌如图 6(b)所示.从图 6(b)可以发现,峰时效态合金中的析出相的尺寸较小,约为10 nm,整体呈现椭球型.利用SAED图谱分析时效析出相的结构特征,选区电子衍射图谱的电子束入射方向平行于Mg[0001],可以观察到除了基体明锐的衍射斑点之外,在镁基体(0001) 面1/4、1/2、3/4的位置处出现了弱衍射斑,该相具有底心正交结构,晶格常数为a=2a(α-Mg)=0.642 nm,$b = 4\sqrt 3 a\left( {\alpha-{\rm{Mg}}} \right) $=2.224 nm,c=c(α-Mg)=0.512 nm,也和基体完全共格,位向关系为〈001〉β′//〈0001〉α,{100}β′//{1120}α[23].因此,由于时效过程中尺寸细小的β′相大量析出且较为均匀地分布在合金基体中,将使合金在塑性变形过程中有效地阻止位错运动,从而显著地提高合金的力学性能.

2.4 合金的力学性能

图 7为合金热挤压态和时效态的室温力学性能.合金挤压态的室温平均力学性能为Rm=306.0 MPa,Rp0.2=234.0 MPa,A=10.6%,硬度值为81 Hv;合金时效态的室温平均力学性能为Rm=397.5 MPa,Rp0.2=359.0 MPa,A=6.0%,硬度值为104 Hv.对比2种状态的力学性能可知,所研究合金具有良好的时效强化效果,合金热挤压后的时效态力学性能显著高于热挤压态合金的力学性能.与热挤压态相比,合金时效后的抗拉强度、屈服强度分别提高了27.0%、53.8%,同时伸长率虽有一定程度降低但仍高于5.0%.

综合前述合金铸态、固溶态、热挤压态及时效态微观组织和力学性能的演变规律,分析认为最终时效态合金力学性能的提高主要原因有以下几个方面:1) 热挤压过程中合金发生了动态再结晶,获得了细小的再结晶晶粒,根据Hall-Patch公式

$$ {\sigma _{\rm{y}}} = {\sigma _0} + K \times {d^{-1/2}} $$ (1) 式中:σy为屈服强度;σ0为单晶体的屈服强度;K为常数,d为晶粒尺寸.由式(1) 可知,晶粒越细小,材料强度越高.而挤压后的合金晶粒尺寸由26 μm减小到10 μm,可显著地提高合金的屈服强度. 2) 铸态粗大的(Mg, Zn)3Gd相易于形成裂纹源,而经固溶处理后的上述(Mg, Zn)3Gd相基本消失,新生成的LPSO结构是有效强化相,可提高合金的塑性变形能力,同时经挤压后的LPSO结构弥散分布于基体,可阻碍位错运动产生形变强化,提高合金强度. 3) 时效过程中,由于LPSO相的存在可钉扎位错阻碍析出相的进一步长大,获得纳米尺寸的β′相,细小的β′相弥散分布于基体中,当合金受到外载荷作用时,位错将与时效析出相发生交互作用,位错运动受到阻碍,从而提高了合金的强度.

3. 结论

1) 开发了高性能Mg-Gd-Er-Zn变形镁合金材料,室温平均力学性能为Rm=397.5 MPa,Rp0.2=359.0 MPa,A=6.0%.

2) 铸态Mg-Gd-Er-Zn合金固溶处理后,形成沿晶界析出的层片状的LPSO结构,该结构可在挤压过程中有效钉扎晶界产生细晶强化作用;Mg-Gd-Er-Zn合金具有良好的时效硬化效果,在热挤压后的时效过程中有大量纳米级时效相β′析出.

3) Mg-Gd-Er-Zn合金中LPSO结构与时效强化相β′的共存,实现了二者共同强化的效果.

-

-

[1] 梁艳, 黄晓锋, 王韬, 等.高强镁合金的研究状况及发展趋势[J].中国铸造装备与技术, 2009(1):8-12. http://www.cnki.com.cn/Article/CJFDTOTAL-ZZSB200901003.htm LIANG Y, HUANG X F, WANG T, et al. The research status and development trend of high strength magnesium alloys[J]. China Casting Equipment and Technology, 2009(1):8-12. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-ZZSB200901003.htm

[2] 陈晓强, 刘江文, 罗成萍.高强度Mg-Zn系合金的研究现状与发展趋势[J].材料导报, 2008, 22(5):58-62. http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200805017.htm CHEN X Q, LIU J W, LUO C P. Research status and development trend of Mg-Zn alloys with high strength[J]. Material Review, 2008, 22(5):58-62. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200805017.htm

[3] 张丁非, 齐福刚, 赵霞兵, 等. Mg-Zn系高强度镁合金的研究进展[J].重庆大学学报, 2010, 33(11):53-61. doi: 10.11835/j.issn.1000-582X.2010.11.009 ZHANG D F, QI F G, ZHAO X B, et al. Research progress of high strength Mg-Zn series alloys[J]. Journal of Chongqing University, 2010, 33(11):53-61. (in Chinese) doi: 10.11835/j.issn.1000-582X.2010.11.009

[4] 程素玲, 杨根仓, 樊建峰, 等.铸造镁合金的发展及其展望[J].材料导报, 2005, 19(2):91-97. http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200502026.htm CHENG S L, YANG G C, FAN J F, et al. The development of casting magnesium alloy and its prospects[J]. Material Review, 2005, 19(2):91-97. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200502026.htm

[5] 余琨, 黎文献, 王日初, 等.变形镁合金的研究、开发及应用[J].中国有色金属学报, 2003, 13(2):277-287. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY200706022.htm YU K, LI W X, WANG R C, et al. Magnesium alloy in the research, development and application[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2):277-287. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY200706022.htm

[6] TONG L B, LI X H, ZHANG H Y. Effect of long period stacking ordered phase on the microstructure, texture and mechanical properties of extruded Mg-Y-Zn alloy[J]. Materials Science and Engineering A, 2013, 563:177-183. doi: 10.1016/j.msea.2012.10.088

[7] 张景怀, 唐定骧, 张洪杰, 等.稀土元素在镁合金中的作用及其应用[J].稀有金属, 2008, 32(5):659-667. http://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200805025.htm ZHANG J H, TANG D X, ZHANG H J, et al. The role of rare earth elements in magnesium alloy and its application[J]. The Chinese Journal of Nonferrous Metals, 2008, 32(5):659-667. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200805025.htm

[8] 刘楚明, 郑梁, 王松涛, 等.高强变形镁合金研究现状及发展趋势[J].宇航材料工艺, 2012(1):8-12. http://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201201005.htm LIU C M, ZHENG L, WANG S T, et al. Research status and development tendency on high strength wrought magnesium alloys[J]. Aerospace Material Process, 2012(1):8-12. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201201005.htm

[9] GAO Y, WANG Q D, GU J H, et al. Effects of heat treatment on microstructure and mechanical properties of Mg-15Gd-5Y-0.5Zr alloy[J]. Rare Earths, 2008, 26(2):298-302. doi: 10.1016/S1002-0721(08)60084-8

[10] 彭卓凯, 张新明, 陈健美, 等. Mn, Zr对Mg-Gd-Y合金组织与力学性能的影响[J].中国有色金属学报, 2005, 15(6):917-922. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200506017.htm PENG Z K, ZHANG X M, CHEN J M, et al. Effects of Mn, Zr on microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6):917-922. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200506017.htm

[11] CHI Y Q, ZHENG M Y, XU C, et al. Effect of ageing treatment on the microstructure, texture and mechanical properties of extruded Mg-8.2Gd-3.8Y-1Zn-0.4Zr (wt%) alloy[J]. Materials Science & Engineering A, 2013, 565:112-117. http://d.scholar.cnki.net/detail/SJES_U/SJES13011502023295

[12] 张松, 袁广银, 卢晨, 等.长周期结构增强镁合金的研究进展[J].材料导报, 2008, 22(2):61-81. http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201617023.htm ZHANG S, YUAN G Y, LU C, et al. Research progress in Mg-based alloys reinforced by long-period ordered structure[J]. Material Review, 2008, 22(2):61-81. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201617023.htm

[13] XU C, ZHENG M Y, WU K, et al. Effect of cooling rate on the microstructure evolution and mechanical properties of homogenized Mg-Gd-Y-Zn-Zr alloy[J]. Materials Science & Engineering A, 2013, 559:364-370. https://www.researchgate.net/publication/257339230_Effect_of_cooling_rate_on_the_microstructure_evolution_and_mechanical_properties_of_homogenized_Mg-Gd-Y-Zn-Zr_alloy

[14] XU C, ZHENG M Y, XU S W, et al. Improving strength and ductility of Mg-Gd-Y-Zn-Zr alloy simultaneously via extrusion, hot rolling and ageing[J]. Materials Science & Engineering A, 2015, 643:137-141.

[15] ZHANG S, LIU W C, GU X Y, et al. Effect of solution and ageing treatments on the microstructures evolution and mechanical properties of Mg-14Gd-3Y-1.8Zn-0.5Zr alloy[J]. Journal of Alloys and Compounds, 2013, 557:91-97. doi: 10.1016/j.jallcom.2012.12.093

[16] 曾小勤, 吴玉娟, 彭立明, 等. Mg-Gd-Zn-Zr合金中的LPSO结构和时效相[J].金属学报, 2010, 46(9):1041-1046. http://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201009005.htm ZENG X Q, WU Y J, PENG L M, et al. LPSO structure and aging phase in Mg-Gd-Zn-Zr alloy[J]. Acta Metallurgica Sinica, 2010, 46(9):1041-1046. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201009005.htm

[17] WEN K, LIU K, WANG Z H, et al. Effect of microstructure evolution on mechanical property of extruded Mg-12Gd-2Er-1Zn-0.6Zr alloys[J]. Journal of Magnesium and Alloy, 2015(3):23-28.

[18] ZHU Y M, MORTON A J, NIE J F. Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys[J]. Acta Materialia, 2012(60):6562-6572. https://www.researchgate.net/publication/257541155_Growth_and_transformation_mechanisms_of_18R_and_14H_in_Mg-Y-Zn_alloys

[19] LIU K, ZHANG J H, LU H Y, et al. Effect of the long periodic stacking structure and W-phase on the microstructures and mechanical properties of the Mg-8Gd-xZn-0.4Zr alloys[J]. Materials and Design, 2010(31):210-219. https://www.researchgate.net/publication/225555383_Effect_of_Zn_concentration_on_the_microstructures_and_mechanical_properties_of_extruded_Mg-7Y-4Gd-04Zr_alloys

[20] WU Y J, LIN D L, DING W J. Formation of a lamellar 14H-type long period stacking ordered structure in an as-cast Mg-Gd-Zn-Zr alloy[J]. Mater Sci, 2009(44):1607-1612. https://www.researchgate.net/publication/238357708_Formation_of_a_lamellar_14H-type_long_period_stacking_ordered_structure_in_an_as-cast_Mg-Gd-Zn-Zr_alloy

[21] 孟令刚. Mg-Gd-Y-Zn-Zr合金长周期结构形成机制与组织性能研究[D]. 沈阳: 大连理工大学, 2014. MENG L G. Researches on formation mechanism of the LPSO structure, microstructures and mechanical properties of the Mg-Gd-Y-Zn-Zr alloys[D]. Shenyang:Dalian University of Technology, 2014. (in Chinese)

[22] 李扬欣. 稀土镁合金中的长周期堆垛有序结构相及其对组织与性能的影响[D]. 上海: 上海交通大学, 2014. LI Y X. The effect of long period stacking ordered phase on mechanical properties in magnesium alloys containing rare earth elements[D]. Shanghai:Shanghai Jiao Tong University, 2014. (in Chinese)

[23] LI Y X, QIU D, RONG Y H, et al. TEM study on the microstructural evolution in an Mg-Y-Gd-Zn alloy during ageing[J]. Intermetallics, 2013(40):45-49. https://researchbank.rmit.edu.au/view/rmit:30895

-

期刊类型引用(7)

1. 段志萌,刘林林,刘翠秀,郅露寒. Zn含量对Mg-Gd-Y-Zn合金微观结构的影响. 有色金属设计. 2024(04): 47-52 .  百度学术

百度学术

2. 刘林林,孙鹏阳,孙威,刘翠秀. Mg-Gd-Y合金中与β′相粗化相关的析出结构. 北京工业大学学报. 2022(02): 164-175 .  本站查看

本站查看

3. 付三玲,李全安,张清. 时效态Mg-12Gd-3Y-1Sm-0.5Zr合金的拉伸蠕变行为. 材料热处理学报. 2022(08): 37-44 .  百度学术

百度学术

4. 徐勇,罗峰. 等温热处理和变形量对体育器械用Mg-6Al-xEr合金组织与力学性能的影响. 热加工工艺. 2021(20): 146-150+154 .  百度学术

百度学术

5. 薛海涛,李小妮,杜威,杨朔. 压缩与半固态等温热处理对Mg-3Al-0.8Gd合金组织与性能的影响. 机械工程材料. 2020(05): 33-37+43 .  百度学术

百度学术

6. 杜文博,贾林玥,王朝辉,刘轲,李淑波,杜宪. 北工大高强稀土镁合金研究进展. 北京工业大学学报. 2020(06): 710-718 .  本站查看

本站查看

7. 张丽凤,王社则,田博彤. 稀土Er对汽车轮毂用A356铝合金组织与性能的影响. 上海金属. 2019(03): 67-72 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: