TiB2 Reinforced Aluminum Matrix Composites Prepared by Rapid Solidification and Hot Extrusion

-

摘要:

为了避免传统铸锭的组织粗大与微观偏析影响材料强度的提升, 采用快速凝固单辊熔体旋转法制备5%TiB2增强Al-Zn-Mg-Cu-Zr-Er复合材料薄带, 其中TiB2颗粒的质量分数为5%, 在380~440 ℃温度下进行热力挤压获得复合材料棒材, 通过X射线衍射、扫描电镜、拉伸测试等分析手段研究TiB2增强铝基复合材料显微组织与力学性能。结果表明: 快速凝固能明显细化复合材料晶粒, 组织均匀, 制备的TiB2增强复合材料带材晶粒尺寸为4~6 μm; 细晶复合材料带材经热挤压得到棒材, TiB2颗粒均匀分布; 随挤压温度升高, 复合材料棒材抗拉强度从381 MPa提升到445 MPa, 晶粒有所长大。综合考虑, 挤压温度420 ℃、保温30 min为最佳快速凝固+热挤压制备复合材料工艺参数。快速凝固技术在铝基复合材料晶粒细化方面有很大潜力。

Abstract:To avoid the coarse microstructures and micro-segregation of traditional ingots affecting the improvement of material strength, a rapid solidification single-roll melt rotation method was used to prepare 5%TiB2/Al-Zn-Mg-Cu-Zr-Er composite material ribbons, composite bars were obtained by hot extrusion at 380-440 ℃, and the microstructures and mechanical properties of TiB2 reinforced aluminum matrix composites were studied by X-ray diffraction, scanning electron microscopy, tensile testing and other analytical methods. Results show that rapid solidification can significantly refine composite grains, microstructure uniformity, the grain size of the prepared TiB2 reinforced composite ribbons are 4-6 μm; fine-grained composite ribbons are hot extruded to obtain bars, and TiB2 particles are uniformly distributed. As the extrusion temperatures increase, the tensile strength of composite bars increases from 381 MPa to 445 MPa, and the grains have grown. The extrusion temperature of 420 ℃ for 30 min is the best rapid solidification and hot extrusion process parameter for preparing composites. Rapid solidification technology has great potential for grain refinement of aluminum matrix composites.

-

Keywords:

- rapid solidification /

- hot extrusion /

- TiB2 particles /

- composites /

- microstructure /

- mechanical properties

-

自1960年以来,Al-Zn-Mg-Cu系铝合金是以空天军工为背景研究并发展起来的一类超高强高韧材料,具有高比强度与硬度、易加工成形、较高的韧性等优点,在航空航天、交通运输、日用品等领域展现出广阔的应用前景[1-3]。其中微纳米尺寸的TiB2颗粒具有低密度、高熔点、高弹性模量等优点,并且与铝合金基体可以生成强的共价键,形成良好的晶格匹配关系[4-6]。为了提高铝合金材料的力学性能,将TiB2颗粒作为增强体引入到铝合金中提升强度,制备颗粒增强铝基复合材料。

对于高锌铝合金而言,锌含量过高会促进铸造缺陷形成,导致材料出现微观偏析、组织粗大和裂纹,所以传统铸造冶金法成品率低,不能在锌质量分数超过8%后继续保持基体合金的高强度和塑性[7-8]。近年来,相关学者对TiB2增强铝基复合材料也进行了一定程度研究。中南大学的凌兴珠等[9]通过熔铸法制备TiB2/6061复合材料,存在与合金界面结合较差、冷却速度慢、TiB2颗粒均匀分布难以控制的问题。上海交大的Chen等[10]、Ma等[11]通过混合盐法制备TiB2/7050与TiB2/7055复合材料,反应过程产生大量有害气体,形成的TiB2增强相被盐膜包覆,削弱增强效果。北京工业大学的Li等[12]通过熔体自蔓延直接反应法制备TiB2/Al-10Zn-1.7Mg-1.0Cu-0.12Zr复合材料,铸态组织形成粗大的晶界析出相,呈树枝网状,导致铸坯及热挤压过程中合金出现开裂现象。这是因为铝合金制备采用的是常规金属型铸造,在凝固过程中冷却速度慢,基体组织容易出现组织粗大,成分偏析严重,对复合材料性能产生一定劣势。因此,不采用传统铸造冶金法制备锌质量分数为10%以上的TiB2增强铝基复合材料。目前,单辊熔体旋转法是快速凝固技术的一种方式,它能够显著细化合金晶粒,增大合金元素固溶度并减少偏析,熔体凝固速率可达到106 K/s,可以有效避免铸造缺陷,得到具有亚微米级别的显微组织[13-16],非常适合制备高锌含量TiB2增强铝基复合材料,后续通过热挤压变形得到致密的块体材料。截至目前,国内外研究人员对快速凝固铝合金开展了广泛的研究,熔体旋转法被大量应用于铝合金[17-19],关注快速凝固带材的显微组织与力学性能的研究。基于熔体旋转法+热挤压制备铝合金的研究也迅速发展,波兰学者Kapinos等[20]采用熔体旋转+热挤压工艺制备Al-9Zn-2.5Mg-1.8Cu合金,挤压态合金抗拉强度为405 MPa,延伸率为17%。华南理工大学甘吉松等[21]采用单辊熔体旋转法+热挤压制备Al-10.7Zn-2.4Mg-0.9Cu挤压棒材,抗拉强度为499.8 MPa,延伸率为15.3%。Meng等[22]采用熔体旋转法+热挤压工艺制备Al-27Zn-1.5Mg-1.2Cu-0.08Zr合金,挤压态合金抗拉强度为485 MPa,延伸率为5.2%。但对单辊熔体旋转法+热挤压制备TiB2增强铝基复合材料至今没有相关报道。

本文通过快速凝固单辊熔体旋转法+热挤压工艺成功制备了不同温度下TiB2颗粒的质量分数为5%的TiB2增强Al-Zn-Mg-Cu-Zr-Er复合材料挤压棒材,并对复合材料的显微组织和力学性能进行系统研究和讨论。

1. 实验部分

1.1 实验材料成分

本实验所用的TiB2增强复合材料,其化学成分如表 1所示。

表 1 实验材料的化学成分及其质量分数Table 1. Chemical composition of experimental materials% 化学成分 Ti B Zn Mg Cu Zr Er Al 质量分数 3.42 1.57 10.50 2.00 1.20 0.12 0.10 余量 1.2 快速凝固TiB2增强复合材料带材制备

先把浇铸的复合材料铸锭切成15 mm×15 mm×100 mm的多个试样。用无水乙醇清洁快速凝固设备腔体后,将切好的长方体试样放入石英试管中,试管底部设有圆孔,直径为1.5 mm。快速凝固单辊甩带机抽真空后,设定感应电流15 A,电压400 V,铜辊轮转速为25 m/s,氩气气氛下压强为0.1 MPa,得到TiB2增强复合材料熔体。将熔体喷射到高速旋转的冷铜轮上进行快速凝固,高速甩出得到TiB2增强复合材料薄带,宽度为3~5 mm,厚度为80~100 μm,带材表面光洁,复合材料薄带两侧相对平整且厚度均匀。

1.3 TiB2增强复合材料热挤压棒材的制备

采用转速为26 000 r/min的高速万能粉碎机,将已经制备的TiB2增强复合材料带材进行高速万能粉碎,得到粉碎细度为40~200目的复合材料粉材。经过四柱液压机冷压成直径为40 mm的圆柱体,压力为18 MPa,加载时间为2 min。将冷压成型的复合材料圆柱体和挤压模具进行加热、保温,加热温度分别为380、400、420与440 ℃,保温时间都是30 min。取出即进行热挤压加工,挤压比为16∶1,挤压成直径为10 mm的TiB2增强Al-Zn-Mg-Cu-Zr-Er复合材料棒材。

1.4 复合材料表征方法

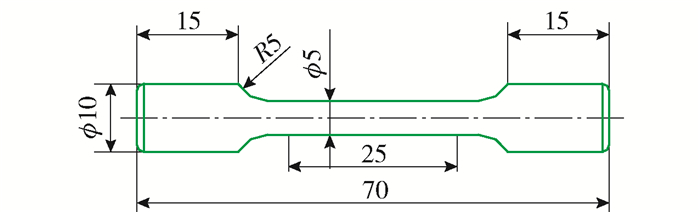

本实验采用X射线衍射仪(D8 ADVACEX)对铸态TiB2增强复合材料和快速凝固带材进行相结构分析。在场发射扫描电镜(Quanta FEG 650)下进行复合材料显微组织及拉伸断口观察。采用电子万能试验机(CMT 5205 GL)对复合材料挤压棒材进行拉伸测试,拉伸速率为0.9 mm/min,按照GB/T228.1—2010规定加工成棒状拉伸试样,如图 1所示。

2. 结果与讨论

2.1 显微组织分析

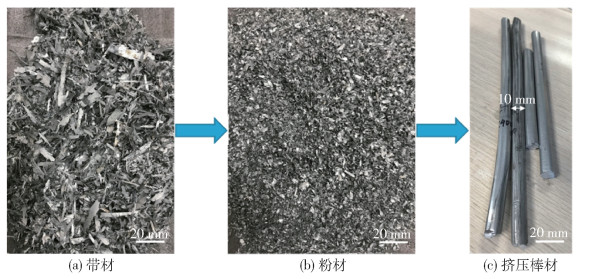

快速凝固单辊熔体旋转法+热挤压制备复合材料挤压棒材工艺流程如图 2所示,高速甩出的TiB2增强复合材料带材宽度为3~5 mm,厚度为80~100 μm。从图 2(a)中宏观形貌可以观察到复合材料薄带表面没有孔洞,具有很好的连续性。采用转速为26 000 r/min的高速万能粉碎机进行粉碎得到TiB2增强复合材料粉材,如图 2(b)所示,粉碎细度为40~200目,粉碎比较均匀。而热挤压变形制备的复合材料棒材宏观形貌如图 2(c)所示,挤压棒材直径为10 mm,可以看到复合材料棒材表面光滑、无裂纹等宏观缺陷,说明热挤压变形促使快速凝固TiB2增强复合材料有效焊合。

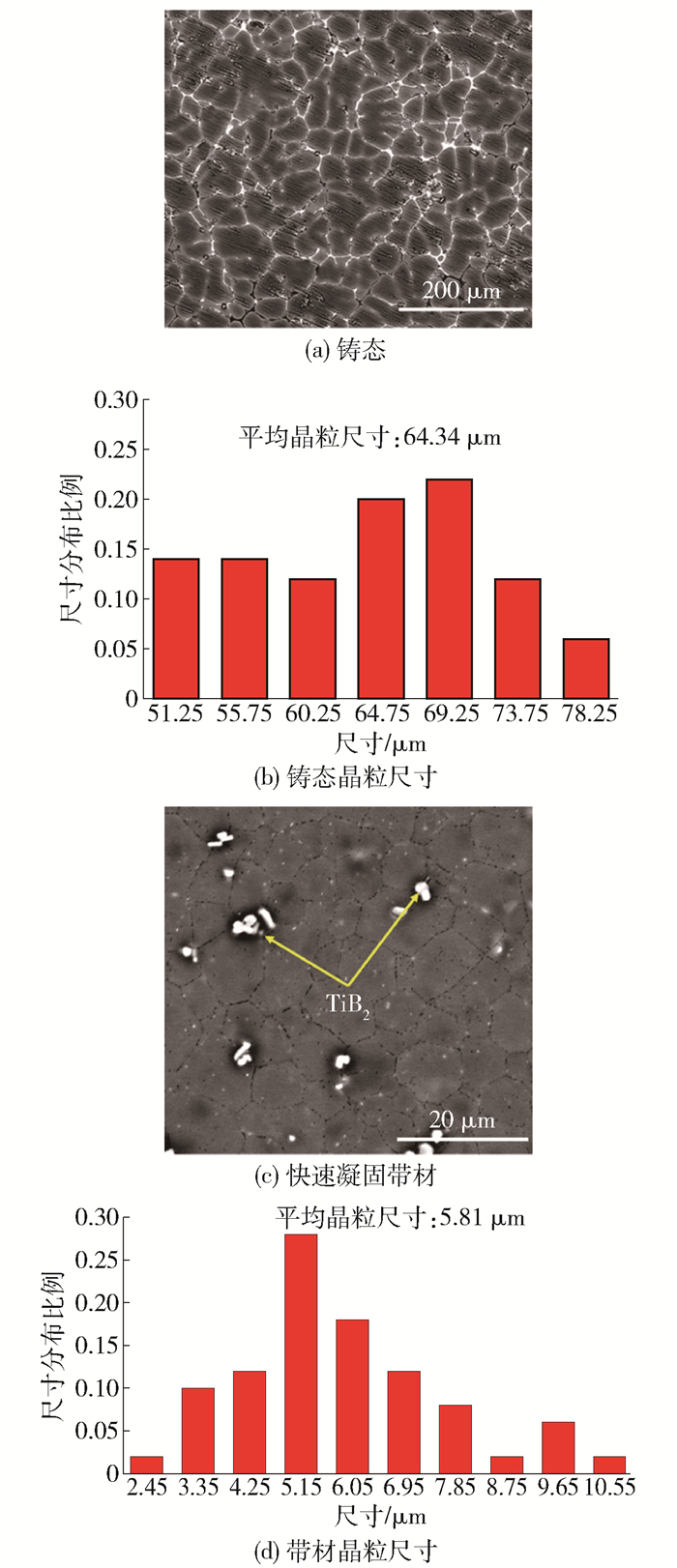

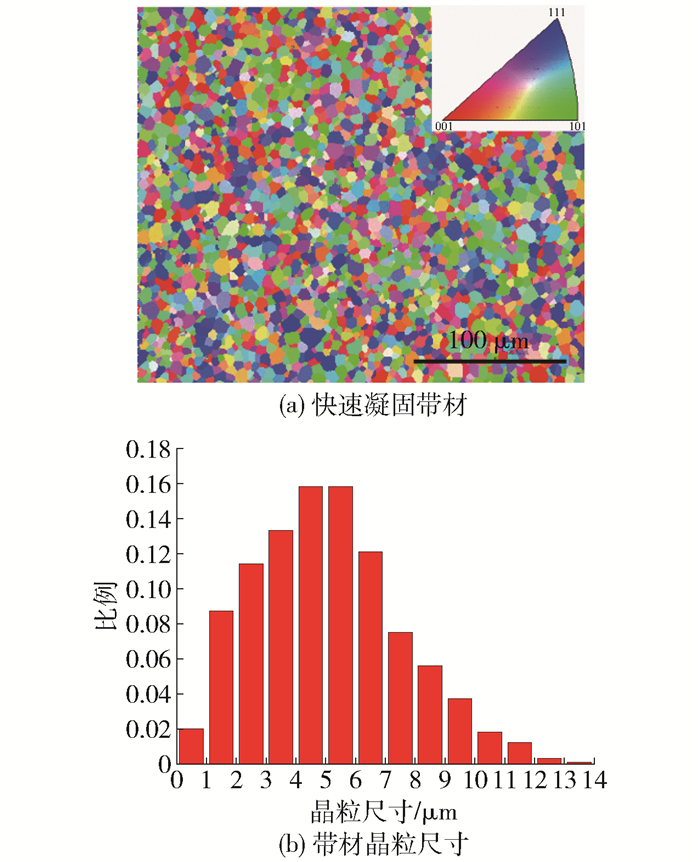

图 3为常规铸造及快速凝固复合材料带材的SEM显微组织、对应晶粒尺寸统计,可以得到常规铸造制备的铸态TiB2增强复合材料,平均晶粒尺寸为64.34 μm。其中图 3(c)为快速凝固复合材料带材显微组织,可以看出为细小的等轴晶,平均晶粒尺寸为5.81 μm,相比于常规铸造,晶粒尺寸细化了90.97%,TiB2颗粒分布于基体合金中,未观察到明显的宏观偏析和第二相,由于快速凝固复合材料中析出相非常少,因此TiB2颗粒在基体显微组织中呈现白亮色。表明铝合金元素在快速凝固过程中,有大量的溶质原子溶解于Al基体得到了过饱和固溶体。为了进一步证明快速凝固技术的优势,利用XRD进行TiB2增强复合材料物相分析。

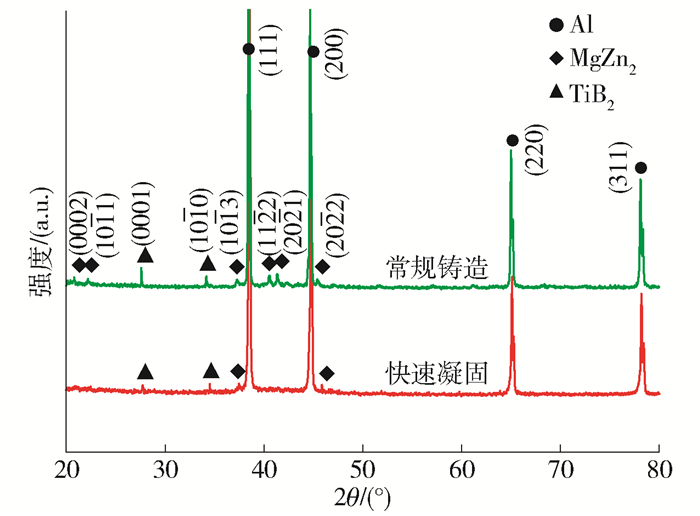

图 4为常规铸造和快速凝固复合材料带材X射线衍射图,可以观察到常规铸造法制备的TiB2增强复合材料铸态除了明显的α (Al)相外,还有大量的MgZn2相和TiB2相,而快速凝固单辊熔体旋转法制备的TiB2增强复合材料有明显的α (Al)相和TiB2相,但衍射峰强度变弱,同时观察到在(1013)与(2022)晶面有微弱的MgZn2相衍射峰,另外研究发现α (Al)衍射峰在一定程度上有所右移,进一步表明快速凝固单辊熔体旋转法促使Zn、Mg、Cu等合金元素大幅度溶于铝基体。铸态TiB2增强Al-Zn-Mg-Cu复合材料在凝固过程中冷却速度慢,容易形成缩孔、缩松等缺陷,而单辊熔体旋转法制备TiB2增强Al-Zn-Mg-Cu复合材料,是将复合材料熔体喷射到高速旋转的冷铜轮上,冷却速度极快,增大了合金元素固溶度,复合材料带材各个部位几乎同时凝固,所以没有出现偏析,得到晶粒尺寸为几个微米的显微组织。在后续的热挤压变形过程中,TiB2增强复合材料会动态析出大量的第二相。

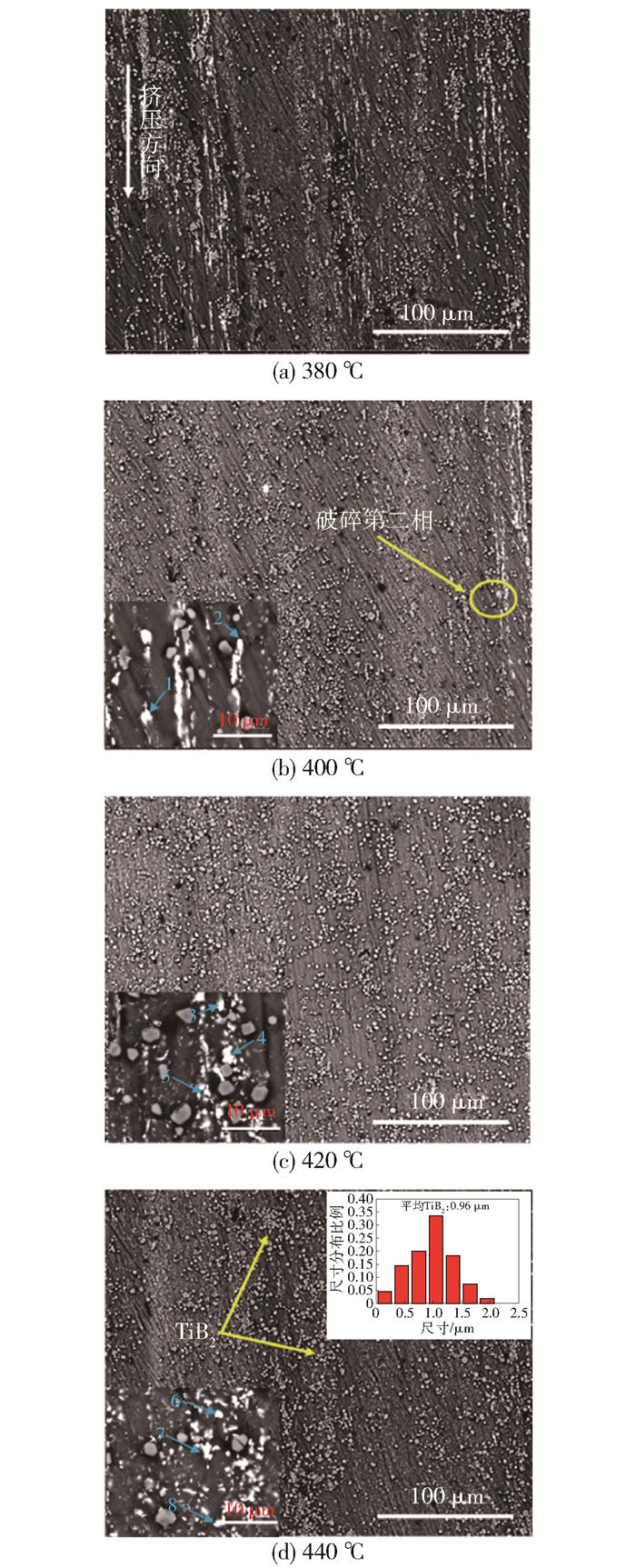

图 5为不同温度下热挤压复合材料棒材的纵截面显微组织,组织面平行于挤压方向,属于特殊的挤压流线状组织,可以观察到沿挤压方向附近存在一些粗大的第二相。对复合材料第二相进行能谱(energy dispersive spectroscopy,EDS)元素分析,如 表 2所示,可以看到Mg与Zn的原子比例接近1∶2,为η相(MgZn2),同时TiB2颗粒沿挤压方向呈线状排列,趋向于均匀分布,具有六方形状且平均颗粒尺寸为0.96 μm。TiB2增强复合材料在热挤压变形过程中,硬脆第二相粒子在外加挤压力的作用下被破碎,根据已报道的文献[20]和能谱测试分析可知,复合材料中除了沿挤压方向分布的η相和TiB2相,可能还有少量的T相(AlZnMgCu)和Al3(Er, Zr)相存在。

表 2 热挤压棒材的第二相化学成分及其粒子数分数Table 2. Second phase chemical composition and atomic percentage of the hot extruded bars点 Al Zn Mg Cu Zr Er 1 76.67 12.23 8.68 2.40 0.02 2 83.04 9.07 5.96 1.82 0.09 0.02 3 76.26 12.83 8.47 2.42 0.02 4 63.01 18.96 13.54 4.41 0.08 5 74.51 13.85 8.96 2.67 0.01 6 74.62 14.28 8.45 2.65 7 81.23 6.82 3.41 7.17 1.36 8 76.17 13.14 8.51 2.18 为了定量研究快速凝固TiB2增强复合材料的晶粒尺寸,采用电子背散射衍射(electron backscattering diffraction,EBSD)技术对其进行组织分析。快速凝固复合材料带材的EBSD组织及晶粒尺寸分布如图 6所示,可以观察到复合材料带材晶粒为细小的等轴状,组织均匀,其平均晶粒尺寸为5.08 μm。华南理工大学廖结莹等[23]对7075铝合金棒材进行快速凝固研究,他们提到快速凝固是一种非平衡的凝固过程,可以在复合材料熔体形成较大起始形核过冷度,此凝固过程中冷却速率很高,所以获得细小且均匀的凝固组织。与图 3的TiB2增强复合材料带材SEM显微组织结果相互佐证。

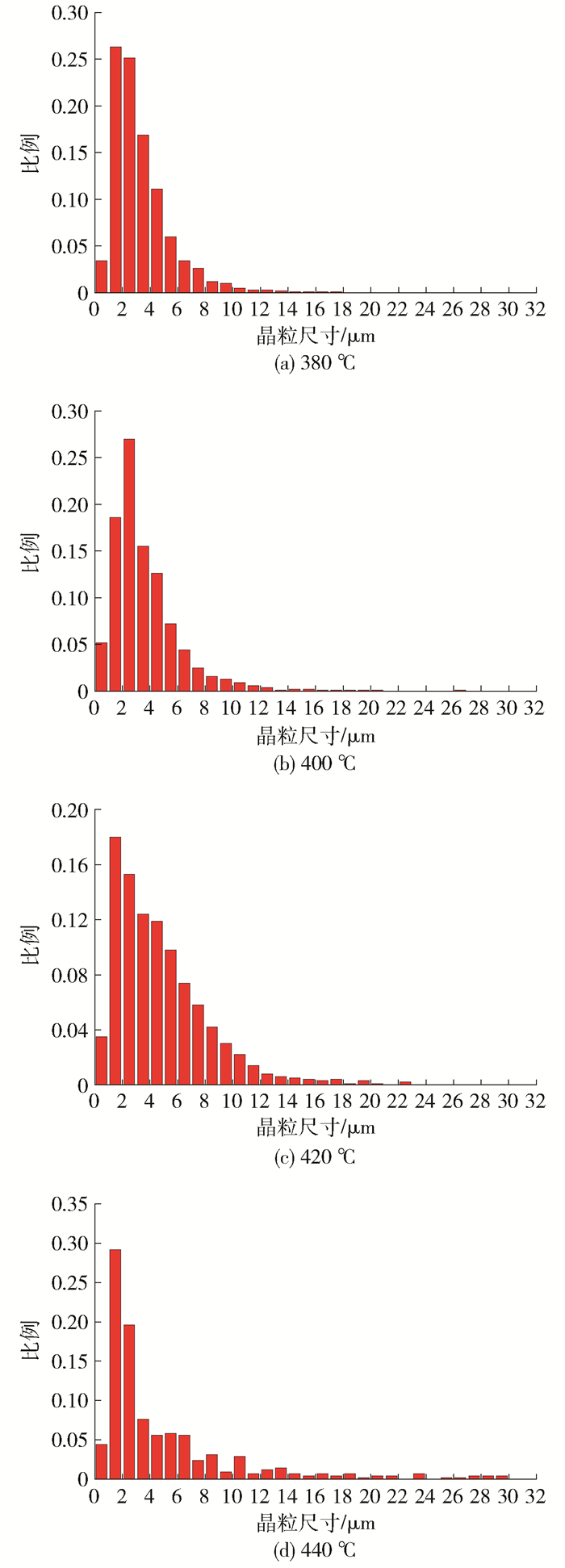

随后,为了进一步确定挤压温度对快速凝固TiB2增强Al-Zn-Mg-Cu复合材料显微组织的影响,对其进行了EBSD组织分析,并对晶粒尺寸进行统计。不同挤压温度下热挤压复合材料棒材的EBSD显微组织及相应的晶粒尺寸分布如图 7、8所示,在挤压温度380 ℃时,复合材料已经出现部分再结晶晶粒,其平均晶粒尺寸为3.48 μm,晶粒尺寸细小。当挤压温度为400、420与440 ℃时,平均晶粒尺寸分别为3.83、4.91与5.75 μm。表明随挤压变形温度的升高,TiB2增强复合材料挤压棒材晶粒不断长大,其平均晶粒尺寸从3.48 μm增大到5.75 μm,这是因为升高挤压温度会促进复合材料动态再结晶的发生和晶粒长大,再结晶程度也有所提升。因此得出,热挤压温度对TiB2增强复合材料晶粒大小有很大影响,随着温度升高,TiB2增强复合材料晶粒有明显的长大倾向。

2.2 力学性能分析

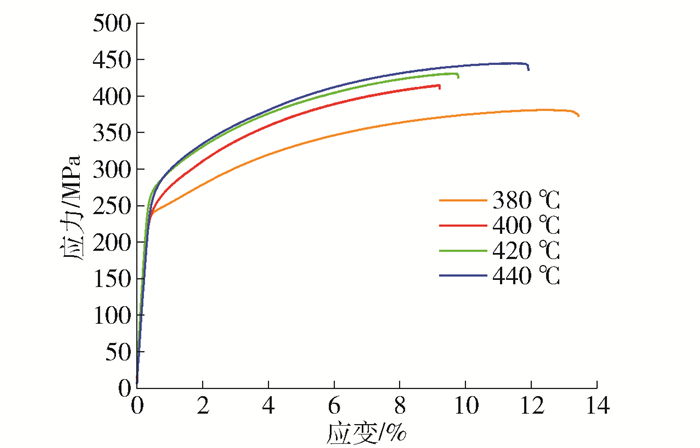

最后,对不同挤压温度下得到的TiB2增强Al-Zn-Mg-Cu复合材料热挤压棒材进行拉伸力学性能对比,如图 9和表 3所示。可以看出,复合材料热挤压棒材在温度380、400、420和440 ℃下抗拉强度分别为381、417、431和445 MPa,延伸率分别为13.4%、9.2%、9.8%和11.9%。在380~440 ℃,热挤压温度越高,TiB2增强复合材料挤压棒材的抗拉强度越高,从381 MPa提升到445 MPa,强度提升约16.8%,而延伸率相差不大。挤压棒材的晶粒尺寸及分布是TiB2增强复合材料抗拉强度和延伸率的最重要影响因素,在挤压温度380 ℃时,复合材料晶粒尺寸最小,在一定体积的晶体内,晶粒数目越多,晶界也就越多,对位错运动的阻碍就越大,复合材料变形的阻力越大,宏观上应该表现为更高的抗拉强度和延伸率,然而在380 ℃热挤压时,复合材料棒材致密度低,快速凝固带材界面结合不紧密,故此时的复合材料棒材抗拉强度不高,延伸率仍然最高。在380~440 ℃,随着挤压温度的升高,复合材料晶粒尺寸越来越大,但带材结合更加紧密,复合材料棒材致密度越来越高,可以得到更加致密的复合材料显微组织,故TiB2增强复合材料抗拉强度越高,延伸率在一定程度上有所提升。综上,TiB2增强复合材料出现上述结果的原因是快速凝固带材在挤压变形过程中,加热温度越高,剪切力作用越强,复合材料带材层与层之间更加紧密,同时带材之间界面结合的孔隙被进一步消除,所以TiB2增强复合材料获得更高强度,故复合材料挤压棒材表现更优异的力学性能。

表 3 不同挤压温度下热挤压棒材的拉伸力学性能参数值Table 3. Parameters of tensile mechanical properties of the hot extruded bar at different extrusion temperatures挤压温度/℃ 抗拉强度/MPa 屈服强度/MPa 延伸率/% 380 381 242 13.4 400 417 257 9.2 420 431 275 9.8 440 445 277 11.9 为了更直观地研究快速凝固+热挤压工艺制备TiB2增强铝基复合材料的力学性能,观察不同挤压温度下热挤压棒材的拉伸断口形貌,如图 10所示。可以发现在温度380 ℃(见图 10(a))下,热挤压棒材断口韧窝较多,有明显的解理面,且存在大量孔洞,以韧性断裂为主,呈现韧脆混合断裂特征,虽然微观上热挤压棒材有细小的晶粒尺寸,但复合材料带材层与层之间结合不紧密,导致拉伸时复合材料强度不高。随挤压温度升高到400 ℃(见图 10(b)),复合材料冶金结合质量提高,带材之间的分层现象越来越不明显,局部可见带材结合界面,对复合材料力学性能仍有不利的影响。如图 10(c)所示,在温度420 ℃下,热挤压棒材拉伸断口形貌明显改善,部分TiB2颗粒存在于韧窝底部,并且在TiB2颗粒周围环绕着一些撕裂棱,说明TiB2颗粒与基体之间良好的界面结合,以韧性断裂为主。当挤压温度升到440 ℃时,如图 10(d)所示,复合材料拉伸断口韧窝较多,韧窝较浅且不均匀,组织更加致密,几乎没有明显带材结合界面,为韧性断裂,这是TiB2增强铝基复合材料力学性能改善的主要原因,晶粒有所粗化,但复合材料的抗拉强度更高,可能是因为更高的温度能得到更致密的组织。表明挤压温度对TiB2增强复合材料致密度和带材结合力有重要影响,升高温度可以有效改善快速凝固复合材料带材之间的结合力,最终提升TiB2增强铝基复合材料力学性能。综上所述,通过对TiB2增强铝基复合材料显微组织和晶粒尺寸统计,拉伸性能测试,同时考虑快速凝固复合材料带材之间的焊合问题,故选择挤压温度420 ℃、保温30 min作为最佳快速凝固+热挤压制备TiB2增强复合材料工艺参数。

3. 结论

通过快速凝固+热挤压技术成功制备了TiB2颗粒的质量分数为5%的TiB2增强Al-Zn-Mg-Cu复合材料热挤压棒材。运用XRD、SEM、EBSD等手段研究TiB2增强铝基复合材料显微组织与力学性能,得到如下结论:

1) 快速凝固能明显细化复合材料晶粒,相比于常规铸造,其平均晶粒尺寸从64.34 μm减少至5.81 μm,晶粒细化90.97%。单辊熔体旋转法制备的TiB2增强Al-Zn-Mg-Cu-Zr-Er带材组织均匀细小,为等轴状,晶粒尺寸为4~6 μm,同时增大了合金元素的固溶度。

2) 采用快速凝固+热挤压制备TiB2增强铝基复合材料挤压棒材,TiB2颗粒均匀分布,在380~440 ℃,抗拉强度从381 MPa提升到445 MPa,强度提升约16.8%,而延伸率相差不大。

3) 热挤压温度越高,TiB2增强铝基复合材料棒材力学性能越好。在相同工艺下,升高挤压温度可以加大快速凝固复合材料带材之间的结合力,促使TiB2增强复合材料带材有效焊合。综合考虑,挤压温度420 ℃、保温30 min为最佳快速凝固+热挤压制备TiB2增强铝基复合材料工艺参数。

-

表 1 实验材料的化学成分及其质量分数

Table 1 Chemical composition of experimental materials

% 化学成分 Ti B Zn Mg Cu Zr Er Al 质量分数 3.42 1.57 10.50 2.00 1.20 0.12 0.10 余量 表 2 热挤压棒材的第二相化学成分及其粒子数分数

Table 2 Second phase chemical composition and atomic percentage of the hot extruded bars

点 Al Zn Mg Cu Zr Er 1 76.67 12.23 8.68 2.40 0.02 2 83.04 9.07 5.96 1.82 0.09 0.02 3 76.26 12.83 8.47 2.42 0.02 4 63.01 18.96 13.54 4.41 0.08 5 74.51 13.85 8.96 2.67 0.01 6 74.62 14.28 8.45 2.65 7 81.23 6.82 3.41 7.17 1.36 8 76.17 13.14 8.51 2.18 表 3 不同挤压温度下热挤压棒材的拉伸力学性能参数值

Table 3 Parameters of tensile mechanical properties of the hot extruded bar at different extrusion temperatures

挤压温度/℃ 抗拉强度/MPa 屈服强度/MPa 延伸率/% 380 381 242 13.4 400 417 257 9.2 420 431 275 9.8 440 445 277 11.9 -

[1] HEINZ A, HASZLER A, KEIDEL C, et al. Recent development in aluminium alloys for aerospace applications[J]. Materials Science & Engineering A, 2000, 280(1): 102-107.

[2] LITYNSKA-DOBRZYNSKA L, OCHIN P, GORAL A, et al. The microstructure of rapidly solidified Al-Zn-Mg-Cu alloys with Zr addition[J]. Solid State Phenomena, 2010, 163: 42-45. doi: 10.4028/www.scientific.net/SSP.163.42

[3] FANG H C, LUO F H, CHEN K H. Effect of intermetallic phases and recrystallization on the corrosion and fracture behavior of an Al-Zn-Mg-Cu-Zr-Yb-Cr alloy[J]. Materials Science & Engineering A, 2017, 684: 480-490.

[4] TJONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites[J]. Materials Science Engineering R, 2000, 29(3/4): 49-113.

[5] MARLAUD T, DESCHAMPS A, BLEY F, et al. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260. doi: 10.1016/j.actamat.2009.09.003

[6] MILMAN V, WARREN M C. Elastic properties of TiB2 and MgB2[J]. Journal of Physics Condensed Matter, 2001, 13(24): 5585-5595. doi: 10.1088/0953-8984/13/24/304

[7] BLAZ L, SUGAMATA M, KULA A, et al. Mechanical consolidation of rapidly solidified meso 20 alloy flakes-structure and mechanical properties[J]. Journal of Alloys and Compounds, 2012, 520: 105-113. doi: 10.1016/j.jallcom.2011.12.142

[8] 李海超. 喷射沉积Al-Zn-Mg-Cu合金成分优化及热加工组织调控[D]. 哈尔滨: 哈尔滨工业大学, 2018. LI H C. Composition optimization and hot working microstructural control of working microstructural control of the spray deposited Al-Zn-Mg-Cu alloy[D]. Harbin: Harbin Institute of Technology, 2018. (in Chinese)

[9] 凌兴珠, 徐振民. TiB2颗粒增强铝合金复合材料研究[J]. 有色金属, 1998(2): 100-104. LING X Z, XU Z M. Study on TiB2 particle reinforced aluminum alloy composites[J]. Nonferrous Metals, 1998(2): 100-104. (in Chinese)

[10] CHEN D, LE Y K, BAI L, et al. Mechanical properties and microstructure of in situ TiB2-7055 composites[J]. Chinese Journal of Aeronautics, 2006, 19(Suppl 1): 66-70.

[11] MA Y, CHEN Z, WANG M L, et al. High cycle fatigue behavior of the in-situ TiB2/7050 composite[J]. Materials Science & Engineering A, 2015, 640: 350-356.

[12] LI H, WANG X M, CHAI L H, et al. Microstructure and mechanical properties of an in-situ TiB2/Al-Zn-Mg-Cu-Zr composite fabricated by Melt-SHS process[J]. Materials Science & Engineering A, 2018, 720: 60-68.

[13] 邓延波, 赵荣涛, 冯骥, 等. 快速凝固技术在铝合金中的应用[J]. 科技信息, 2012(25): 476-477. DENG Y B, ZHAO R T, FENG J, et al. Application of rapid solidification technology in aluminum alloy[J]. Science and Technology Information, 2012(25): 476-477. (in Chinese)

[14] SZYMANEKA M, AUGUSTYN B, KAPINOS D, et al. The production of material with ultrafine grain structure in Al-Zn alloy in the process of rapid solidification[J]. Archives of Foundry Engineering, 2014, 14(2): 57-62. doi: 10.2478/afe-2014-0037

[15] SALEHI M, DEHGHANI K. Structure and properties of nanostructured aluminum A413.1 produced by melt spinning compared with ingot microstructure[J]. Journal of Alloys and Compounds, 2008, 457(1/2): 357-361.

[16] FLORES-CAMPOS R, ESTRADA-GUEL I, MIKI-YOSHIDA M, et al. Microstructure and mechanical properties of 7075 aluminum alloy nanostructured composites processed by mechanical milling and indirect hot extrusion[J]. Materials Characterization, 2012, 63(1): 39-46.

[17] KATGERMAN L, DOM F. Rapidly solidified aluminium alloys by melt spinning[J]. Materials Science & Engineering A, 2004, 375/376/377(1): 1212-1216.

[18] CHEN Z W, FAN Q Y, ZHAO K. Microstructure and microhardness of nanostructured Al4.6CuMn alloy ribbons[J]. International Journal of Minerals, Metallurgy, and Materials, 2015, 22(8): 860-867. doi: 10.1007/s12613-015-1143-6

[19] CHEN Z W, ZHAO J, CHEN P. Microstructure and mechanical properties of nanostructured A8006 ribbons[J]. Materials Science & Engineering A, 2012, 552: 189-193.

[20] KAPINOS D, SZYMANEK M, AUGUSTYN B, et al. Effect of heat treatment on the mechanical properties of wrought Al-Zn-Mg-Cu alloy cast by rapid solidification[J]. Materials Science Forum, 2013, 765: 496-500.

[21] 甘吉松, 张大童, 梁光兴, 等. 快速凝固+热挤压制备Al-10.7Zn-2.4Mg-0.9Cu合金的组织和性能[J]. 材料热处理学报, 2020, 41(1): 27-32. GAN J S, ZHANG D T, LIANG G X, et al. Microstructure and properties of Al-10.7Zn-2.4Mg-0.9Cu alloy prepared by rapid solidification and hot extrusion[J]. Transactions of Materials and Heat Treatment, 2020, 41(1): 27-32. (in Chinese)

[22] MENG X N, ZHANG D T, ZHANG W W, et al. Microstructure and mechanical properties of a high-Zn aluminum alloy prepared by melt spinning and extrusion[J]. Journal of Alloys and Compounds, 2020, 819: 152990.

[23] 廖结莹, 金硕勋, 李烈军, 等. 熔体旋转快速凝固和热挤压制备7075铝合金棒材[J]. 特种铸造及有色合金, 2019, 39(6): 600-603. LIAO J Y, JIN S X, LI L J, et al. Fabrication of a 7075 aluminum alloy bar through melt spinning and hot extrusion[J]. Special Casting & Nonferrous Alloys, 2019, 39(6): 600-603. (in Chinese)

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: