Preparation of Amorphous Y2O3 Film by SDP Method for Surface Refining of Hastelloy C-276 Alloy Tapes

-

摘要:

为了解决哈氏(Hastelloy C-276)合金基带表面粗糙度过大造成不平整的问题,采用溶液沉积平整化技术在哈氏合金表面制备Y2O3非晶薄膜来满足使用要求.通过研究前驱液的稳定性和浓度、热处理温度和涂覆次数对表面粗糙度的影响规律,同时采用高低浓度相结合的方法涂覆非晶薄膜来提高涂覆效率,结果表明:先使用高浓度0.40 mol/L涂覆6次,再使用低浓度0.10 mol/L涂覆6次,获得了表面平均粗糙度Ra值为0.65 nm(5 μm×5 μm)高表面质量的带材,涂覆效率相比使用单一溶度提高了近30%.前驱液浓度越高,溶液粒径越大,前期涂覆效果更佳,后改用低浓度粒径小的前驱液进行表面精修,可以大幅提高涂覆效率.

Abstract:Hastelloy C-276 alloy is the preferred substrate material for preparing second generation of high temperature coated conductors by ion beam assisted deposition. As to Hastelloy C-276 alloy substrate, the Y2O3 amorphous film was prepared directly on the Hastelloy alloy surface via solution deposition planarization technology to meet the subsequent requirements. The effects of precursor stability, precursor concentration, heat treatment temperature and coating times on surface roughness were studied. Meanwhile, focused on the combination of high and low concentration, the coating efficiency was improved. Results show that the coating with a high concentration of 0.40 mol/L for 6 times, and then coating with a low concentration of 0.10 mol/L for 6 times, a high surface quality substrate with the surface average roughness Ra of 0.65 nm (5 μm×5 μm) is obtained, and the coating efficiency is improved by nearly 30% compared with the solution of a single solubility. When the concentration of precursor solution is high, the solution particle size is large, and the earlier coating effect is better. After that, the precursor solution with small particle size in low-concentration solution was used to modify the surface, which can greatly improve the coating efficiency.

-

第二代高温超导材料YBa2Cu3O7-δ(YBCO)因具有高的不可逆场、载流能力和低的交流损耗等优异性能[1-2],在电力、交通等[3-5]领域具有广阔的应用前景而受到广泛关注. 离子束辅助沉积(ion beam assisted deposition,IBAD)技术[6]是制备第二代高温涂层导体的主要路线之一,其中哈氏(Hastelloy C-276)合金是IBAD路线的首选基带材料[7-8]. IBAD路线是以在无织构的金属基底上制备获得具有织构的过渡层,再利用外延生长的方法获得具有织构的YBCO超导层,其结构包括基板层、过渡层、YBCO层和保护层. 通常金属基本层表面质量较差,通过在金属表面沉积多层非晶薄膜来降低粗糙度从而达到整平效果,以改善合金带材表面质量. 由于在后续沉积MgO的过程中,织构形成的好坏很大程度上取决于基底的表面粗糙度,表面粗糙度Ra值越低,越有利于MgO面内织构的形成,因此需要降低其表面粗糙度. 目前由于国内采用轧制方法制备的哈氏合金带材工艺水平的限制,大多使用的哈氏合金基带均为国外采购[9-10]. 溶液沉积平整化(solution deposition planarization, SDP)技术可通过在金属表面沉积多层非晶薄膜来达到整平效果[11]而成为改善合金带材表面质量的一种方法. 美国Los Alamos国家实验室及Sandia国家实验室在原始哈氏合金基底上使用SDP技术沉积了18层非晶Y2O3薄膜[12-14]. 2005年,澳大利亚的Csiro实验室首次将溶液沉积平整化技术应用在第二代高温涂层导体带材的制备上[15],得到的哈氏合金表面平均粗糙度由28 nm降至1 nm(5 μm×5 μm)以下,最终通过IBAD-MgO沉积过渡层和YBCO超导层,得到J为2.85 MA/cm2(77 K,自场条件下)的超导薄膜. 研究表明,SDP技术降低基带的表面粗糙度是通过溶液收缩实现的,随着涂覆次数的增加,基带的表面粗糙度逐渐降低[16].

国内的上海交通大学和成都电子科技大学也进行了SDP-Y2O3的研究. 文献[17-18]在镜面轧制的哈氏合金上通过SDP技术(浸渍提拉法)涂覆了Gd2Zr2O7(GZO)和Y2O3混合非晶薄膜,获得平均粗糙度Ra值为4.2 nm(50 μm×50 μm)的合金基带;陶伯万课题组采用浸渍提拉法制备出了表面粗糙度小于1.00 nm的20层钇铝氧化物薄膜,并在此非晶薄膜上制备出纯c轴取向的MgO薄膜[19-20].

针对原始带材表面平均粗糙度过大且涂覆次数过多的问题,本文采用SDP技术在哈氏合金带材表面制备非晶薄膜. 本文重点采用高低浓度前驱液相结合的方式制备非晶薄膜,进一步提高涂覆效率,其研究具有很强的科学意义及社会价值.

1. 实验方法

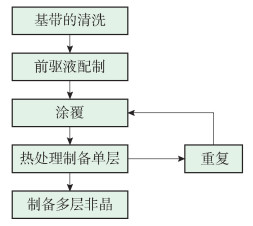

SDP法制备非晶薄膜的具体实验过程包括:前驱液的配制、涂覆和热处理,见图 1. 首先将Ra值约为25 nm(5 μm×5 μm)的哈氏合金长带剪为1 cm×1 cm大小的基片,将基片放入盛有丙酮的烧杯中,超声波清洗3~5 min,主要用来清洗合金表面的非极性残留污物;接着将清洗完的基片放入盛有酒精的烧杯中继续超声3~5 min,以去除合金表面的极性残留污物,清洗后的基片放入真空干燥箱备用.

本文使用的SDP前驱液[21]包括溶质(醋酸钇)、溶剂(乙醇)和添加剂(二乙醇胺). 配制溶液时,分别称取0.85、8.45、16.9、25.35、33.8 g的醋酸钇粉末溶入到200 mL乙醇中,再按照溶质与添加剂物质的量比例为1∶3加入添加剂,用乙醇定容至250 mL得到Y3+离子浓度分别为0.05、0.10、0.20、0.30、0.40 mol/L的前驱液;接着将配置好的前驱液放入温度为40~60 ℃的磁力搅拌器中搅拌2~5 h,使其混合均匀;最后将搅拌后的溶液用针孔式过滤器进行过滤,进一步把不溶性杂质去除. 实验采用KW-4A型匀胶机涂覆薄膜,将清洗后的基底置于匀胶机的吸盘上,并抽真空固定住基片,滴涂少量前驱液于基底上,同时开启电动机让基片做高速旋转,利用离心力的作用使溶液均匀地分布于基底表面,匀胶机转速为3 000 r/min,匀胶时间为30 s. 为除去前驱膜中多余的乙醇溶剂,涂覆完成后立即将前驱湿膜放入120 ℃的干燥箱内干燥3 min.

在哈氏合金上沉积Y2O3非晶薄膜的实验中,热处理是关键的一步,影响着前驱液膜的热分解和结晶情况,进而影响哈氏合金表面粗糙度的大小. 通过TGA测试结果表明450~600 ℃的温度范围内Y(CHCOO)3·4H2O完全分解为Y2O3. 为了深入探究热处理温度对Y2O3非晶薄膜表面粗糙度的影响,设计实验如下:在常压空气条件下采用马弗炉(1700X)对前驱液膜进行热处理,温度分别选取为470、500、530、560、590 ℃,热处理时间为10 min,涂覆3层后分析表面粗糙度与热处理温度的关系. 这里选定Y2O3前驱液为0.4 mol/L,转速为3 000 r/min和涂覆时间为30 s.

本文采用热天平对前驱体溶液进行热重分析;使用ZS90纳米粒度电位仪对不同浓度的前驱液粒径大小进行测试,每种浓度前驱液的测试次数为3次,采用体积分布来表征粒径大小的结果;利用布鲁克X射线衍射仪(X-vay diffraction,XRD)和扫描电子显微镜对哈氏合金进行物相和表面形貌分析;利用原子力显微镜(atomic force microscope,AFM)的非接触模式进行表面粗糙度检测分析.

2. 结果与讨论

在实验中发现配置的0.40、0.10 mol/L前驱液静置24 h后变成白色乳浊液而无法使用,如图 2所示. 分析溶液变质原因可能为金属盐在混合溶剂中溶解度较高或添加剂(二乙醇胺)凝结点比较低,故将醋酸钇和二乙醇胺物质的量比调整为1∶4、1∶5、1∶6,将前驱液的储存温度升高到30、35、40、45 ℃,放置24 h后都仍会出现白色乳浊液.

根据文献[22]说明,配制溶液时加入胺类物质的主要原因是醋酸钇在乙醇中溶解度有限,靠胺类物质螯合金属离子来形成澄清透明的溶液,但二乙醇胺不仅对金属离子具有螯合作用,还能对前驱液膜热分解时的黏性流动起到改善作用,降低液膜开裂的概率. 因此在原有溶液配方基础上,增加添加剂的种类,选择二乙烯三胺作为第2种添加剂. 当醋酸钇与二乙醇胺、二乙烯三胺物质的量比为1∶3∶3时,配制所得前驱液澄清透明,且可稳定保存4周. 但在涂覆实验中发现,由于0.40、0.30 mol/L 前驱液黏度过大,溶液在基底上不能完全铺展,液膜分布不均匀. 故再次调整前驱液配比,醋酸钇与二乙醇胺、二乙烯三胺物质的量比为1∶1.5∶1.5,配制所得前驱液澄清透明且黏度适中,并可稳定保存4周,最终满足实验要求. 分析原因认为,醋酸钇是双齿链化学结构,而二乙醇胺和二乙烯三胺又分别含有1个和3个氨基孤电子对,在加入二乙醇胺后,乙醇中的质子会被其夺走,生成有着很强亲核能力的(CH3CH2O)-. 而(CH3CH2O)-会促使Y(CH3COO)3生成一种可溶性络合物[Y(CH3COO)3(CH3CH2O)2]2-,这种络合物发生水解反应生成的不带电的中间物通过羟联聚合作用合成稳定透明的溶胶[23].

使用ZS90纳米粒度电位仪分别对0.40、0.30、0.20、0.10、0.05 mol/L 5种不同浓度的前驱液粒径大小进行了测试,测试结果显示:每种浓度的前驱液颗粒体积分布都只出现1个峰,没有团聚的大颗粒现象的出现,说明前驱液较为稳定均匀,且平均粒径大小依次为4.8、3.0、1.5、0.9、0.6 nm.

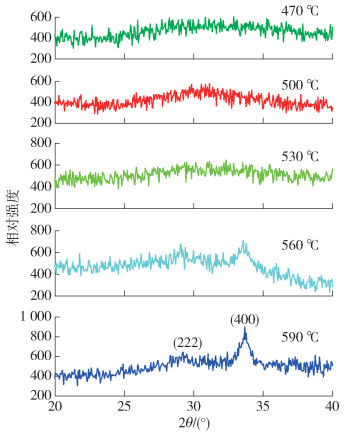

图 3为不同热处理温度条件下Y2O3薄膜XRD图. 从图中可以看出,当热处理温度为470~530 ℃时,XRD测试的结果都没有出现强峰,说明在沉积过程中并没有出现Y2O3的结晶,得到的薄膜为Y2O3非晶薄膜;当温度达到560 ℃时,XRD图谱分别在29、34 ℃附近都出现鼓包状的凸起,且590 ℃凸起的强度和宽度都比560 ℃大,对比标准PDF卡片,得知29 ℃附近的鼓包状的凸起对应于Y2O3的(222)峰位,34 ℃附近的鼓包状的凸起对应于Y2O3的(400)峰位,说明当热处理温度达到560 ℃时,Y2O3薄膜开始出现部分结晶,且随着热处理温度的升高,结晶度也逐渐增大. 此外,对前驱液进行热重分析发现,温度在460 ℃以上,才开始有Y2O3产物分解生成. 其中,在470~530 ℃阶段,XRD测试显示薄膜为非晶状态;从560 ℃开始,薄膜为晶体状态,且热处理温度为530 ℃时,薄膜表面较为平整、无裂纹、满足实验要求. 故确定热处理温度为530 ℃左右时得到薄膜为理想Y2O3非晶薄膜.

分析Y2O3薄膜的结晶情况,主要有以下2个原因:1)晶体的薄膜会出现各向异性,从而导致表面应力的差别,另外,由于结晶过程中晶粒生长的不可控性,使晶粒大小、晶面间距等要素产生差异,结晶薄膜表面会因此产生不同程度的凸起,导致薄膜表面粗糙度增大. 2)结晶的氧化物薄膜会存在许多阴离子空位,这就为基带层和超导层之间的元素提供了扩散通道,元素互扩散严重影响了涂层导体的超导性能[23]. 因此,分析Y2O3薄膜的结晶情况一方面可以确保得到的是非晶薄膜,另一方面又说明了非晶薄膜的粗糙度要比晶体薄膜低,这正是笔者所需要的.

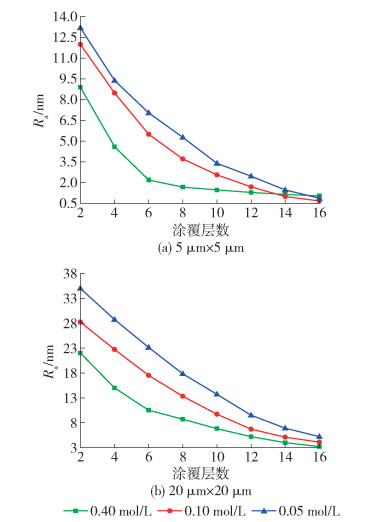

图 4为配制的不同浓度的前驱液涂覆12层Y2O3薄膜得到的三维AFM形貌图. 从图中可以看出,低浓度的前驱液涂覆得到的Y2O3非晶薄膜表面较为平整致密,这是因为低浓度的前驱液涂覆的液膜较薄,得到的薄膜粗糙度也较低,表现为较平整. 从AFM形貌图可以清楚地看出,浓度越低的前驱液制备的薄膜表面粗糙度越低,随着浓度增大,表面平整性趋于凹凸不平,粗糙度也随着变大. 分析发现:前驱液浓度较大,改善表面粗糙度效果较好. 这是因为浓度不同的前驱液中的粒径大小也不相同,浓度高的前驱液中粒径较大. 涂覆层数低时,对表面凹坑的填充效果更佳,表面粗糙度的降低效果更明显;而随着涂覆层数的增加,低浓度的前驱液中粒径尺寸小,涂覆效果优于高浓度.

从图 5中可发现,0.40 mol/L的前驱液在涂覆的前6次过程中,表面平均粗糙度Ra值下降的速率较快,之后Ra值出现平缓的下降趋势,而0.10、0.05 mol/L的前驱液涂覆后,Ra值的下降速率并没有出现明显的变化. 涂覆到16层时,0.40、0.10、0.05 mol/L的前驱液对应的薄膜表面Ra值依次为1.05、0.68、0.88 nm. 说明涂覆16层时,0.10 mol/L的前驱液涂覆效果更佳,且可发现随着涂覆层数的增多,表面粗糙度减小的趋势变缓,此时低浓度的前驱液涂覆效果更优.

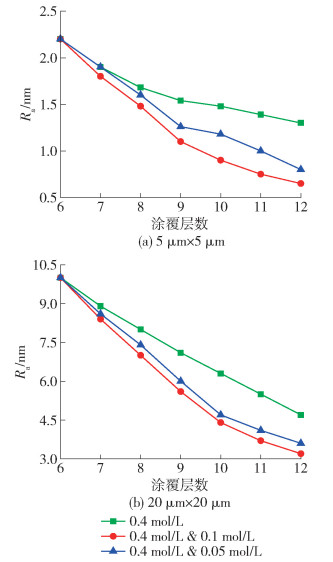

再次观察图 5可发现,采用0.40 mol/L的前驱液涂覆6层后Ra值到达拐点,继续涂覆Ra值的下降速率变得平缓,涂覆6层时,5 μm×5 μm范围内测量Ra值为2.20 nm,继续使用高浓度前驱液涂覆效果变化不大,改用低浓度前驱液继续涂覆,尝试提高涂覆效率. 对哈氏合金进行SDP涂覆,在涂覆6层后,改用0.05、0.10 mol/L的前驱液分别继续涂覆,探究高低浓度相结合的方式对表面粗糙度的影响规律. 其中,涂覆效率可以通过涂覆次数的多少来表征,涂覆次数多,涂覆效率低;哈氏合金基带主要需满足表面粗糙度的要求,涂覆质量也就是Ra值的大小,涂覆质量最高,Ra值越小,涂覆初期涂覆次数越多,Ra值越小,涂覆质量越高,后期Ra值达到一个极值后,涂覆次数跟涂覆质量不挂钩. 涂覆物质为非晶Y2O3薄膜,物相组成基本一致. 已对文中相关表述进行了修改. 因此,涂覆效率与涂覆质量的关系表现为,涂覆次数越多,涂覆层厚度越薄,表面粗糙度越低,涂覆质量越好. 但涂覆次数超过12次后,两者的关系不再如此. 在这种情况下,对于涂覆效率和涂覆质量,需要选择一个合适实验的最优者. 图 6为高低浓度相结合涂覆后表面平均粗糙度Ra值随层数变化曲线,图 6(a)为扫描范围为5 μm×5 μm的变化曲线,可以看出,用低浓度前驱液涂覆2层,也就是第8层的时候,0.05、0.10 mol/L所对应的Ra值开始低于0.40 mol/L,并且0.10 mol/L对应的Ra值要比0.05 mol/L低,到第12层的时候0.40、0.10、0.05 mol/L的前驱液对应的薄膜表面Ra值依次为1.30、0.65、0.80 nm,达到单独使用0.40、0.10、0.05 mol/L前驱液涂覆16层的效果. 图 6(b)为扫描范围为20 μm×20 μm时Ra值的变化曲线,与5 μm×5 μm的扫描范围有类似的趋势,涂覆到第12层,也同样达到单独使用0.40、0.10、0.05 mol/L前驱液涂覆16层的效果.

根据以上分析可以得出,先用0.40 mol/L前驱液涂覆6层,再用0.10 mol/L的前驱液涂覆6层,其表面平均粗糙度Ra值降到0.65 nm(5 μm×5 μm),涂覆效率相比单独使用0.40 mol/L前驱液提高了近30%. 程崛[19]使用0.40、0.10 mol/L单一浓度涂覆制备非晶薄膜,涂覆10层后表面粗糙度各为1.97、1.08 nm,本实验采用高低浓度结合涂覆9层时,其表面平均粗糙度Ra值就可以降到1.07 nm(5 μm×5 μm)左右,且在涂覆12层后表面粗糙度仅为0.65 nm(5 μm×5 μm),大大降低了表面粗糙度.

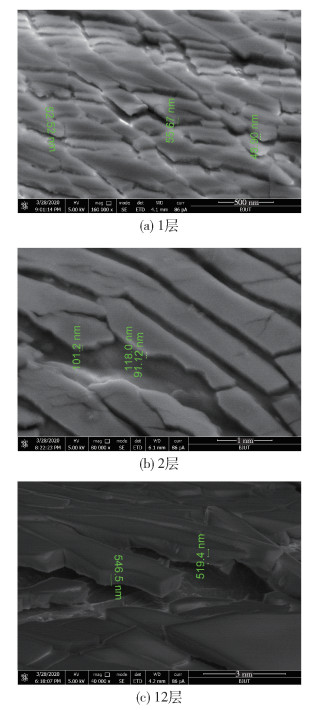

对于多道涂覆,单道涂覆层厚度越薄,表面粗糙度越小. 从图 7可以观察到,由于合金表面粗糙度较大,涂覆前2层时,表面残留的前驱液膜较厚,单层厚度分别为52 nm和51 nm左右,此时表面粗糙度Ra约为9.00 nm(5 μm×5 μm). 随着涂覆次数的增加,合金表面粗糙度Ra值随之下降,表面残留的薄膜厚度也随之减小. 涂覆12层时,薄膜厚度约为533 nm,每一层的平均厚度大约为44 nm,而此时表面粗糙度Ra为0.65 nm(5 μm×5 μm). 而前者[19]涂覆的10层薄膜厚度就已经达到900 nm. 相较之下,本研究采用这种结合方式有效降低表面粗糙度的同时,极大地减小了涂覆薄膜层的厚度,满足使用要求.

3. 结论

针对哈氏合金基带表面,本文采用SDP技术来降低其表面粗糙度. 研究结果表明:

1) 溶质醋酸钇与添加剂二乙醇胺和二乙烯三胺物质的量比为1∶1.5∶1.5,获得的前驱液澄清透明且黏度适中,能够满足实验要求.

2) 涂覆实验中先采用0.40 mol/L前驱液涂覆6层后,改用0.10 mol/L的前驱液涂覆6层,其表面平均粗糙度Ra值降到0.65 nm(5 μm×5 μm),涂覆效率相比单独使用0.40 mol/L前驱液提高了近30%,涂覆12层薄膜的厚度约为533 nm.

3) 前驱液浓度较高时,溶液粒径大且黏度较大,前期可以快速降低其表面粗糙度,在此基础上,改用低浓度前驱液涂覆可进一步降低表面粗糙度达到表面精修的目的.

-

-

[1] 张超, 王飞, 李凯, 等. 实用化高温超导材料的新进展[J]. 热加工工艺, 2017, 46(14): 7-10. https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201714002.htm ZHANG C, WANG F, LI K, et al. New progress in practical high temperature superconducting materials[J]. Hot Processing Technology, 2017, 46(14): 7-10. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201714002.htm

[2] 杨本康, 张东, 李秋君. 高温超导限流电缆研究现状与发展趋势综述[J]. 低温与超导, 2019, 47(9): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-DWYC201909001.htm YANG B K, ZHANG D, LI Q J. A review of the research status and development trend of high temperature superconducting current limiting cables[J]. Low Temperature and Superconductivity, 2019, 47(9): 1-7. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DWYC201909001.htm

[3] ANDREJ K, MATHIAS N, CHRISTIAN S, et al. Investigation of YBCO coated conductor for application in resistive superconducting fault current limiters[J]. IEEE Transactions on Applied Superconductivity, 2007, 17(2): 3499-3502. doi: 10.1109/TASC.2007.899578

[4] YAGI M, MUKOYAMA S, AMEMIYA N, et al. Progress of 275 kV-3 kA YBCO HTS cable[J]. Physica C Superconductivity, 2011, 471(21): 1274-1278. http://www.sciencedirect.com/science/article/pii/S0921453411002644

[5] RAHELEH M, HANI H, JOHN G S, et al. Surface nano-modification by ion beam-assisted deposition alters the expression of osteogenic genes in osteoblasts[J]. Proceedings of the Institution of Mechanical Engineers Part H Journal of Engineering in Medicine, 2019, 233(9): 921-930. doi: 10.1177/0954411919858018

[6] YAMADA Y, WATANABE T, MUROGA T, et al. Rapid production of buffered substrates and long length coated conductor development using IBAD, PLD methods and "Self-Epitaxial" ceria buffer[J]. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 2600-2603. doi: 10.1109/TASC.2005.847666

[7] XUE Y, ZHANG Y H, ZHANG F, et al. Growth of simplified buffer template on flexible metallic substrates for YBa2Cu3O7-δ coated conductors[J]. Journal of Alloys and Compounds, 2016, 673: 47-53. doi: 10.1016/j.jallcom.2016.02.175

[8] PRUSSEIT W, NEMETSCHEK R, HOFFMANN C, et al. ISD process development for coated conductors[J]. Physica C Superconductivity & Its Applications, 2005, 426(2): 866-871. http://www.sciencedirect.com/science/article/pii/S092145340500376X

[9] PARANS M P, TOLGA A, LILIANA S, et al. Chemical solution derived planarization layers for highly aligned IBAD-MgO templatesC[J]. Superconductor Science and Technology, 2014, 27(2): 022002. doi: 10.1088/0953-2048/27/2/022002

[10] MATIAS V, HAENISCH J, ROWLEY E J, et al. Preparation of Substrates for IBAD-MgO coated conductors[J]. MRS Proceedings, 2007, 1001: 2-4. http://journals.cambridge.org/article_S1946427400596365

[11] 储静远, 赵跃, 吴蔚, 等. 溶液沉积平整化工艺用于制备第二代高温超导带材的研究进展[J]. 材料导报, 2016, 30(23): 109-113. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201623016.htm CHU J Y, ZHAO Y, WU W, et al. Research progress of solution deposition flattening process for preparation of second generation high temperature superconducting tapes[J]. Materials Report, 2016, 30(23): 109-113. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201623016.htm

[12] CHRIS S, YEHYUN J, TERRY H, et al. Solution deposition planarization of long-length flexible substrates[J]. Applied Physics Letters, 2011, 98(7): 71907[2011-02-15]. http://aip.scitation.org/doi/10.1063/1.3554754.

[13] LIJIMA Y, HOSAKA M, TANABE N, et al. Biaxial alignment control of YBa2Cu3O7-x films On random Ni-based alloy with textured yttrium stabilized-zriconia films formed by ion-beam-assisted deposition[J]. Journal of Materials Research, 1997, 12(11): 2913-2923. doi: 10.1557/JMR.1997.0386

[14] LIJIMA Y, KAKIMOTO K, SOUOH Y, et al. Development of long Y-123 coated conductor by ion-beam-assisted-deposition and the pulsed-laser-deposition method[J]. Superconductor Science & Technology, 2004, 17(5): S264-S268. http://www.ingentaconnect.com/content/iop/sust/2004/00000017/00000005/art00033

[15] GNANARAJAN S, DU J. Flexible YBa2Cu3O7-δ-coated superconductor tapes on non-metallic substrates with spin-on-glass and IBAD-YSZ buffer layers[J]. Superconductor Science & Technology, 2005, 18(4): 381[2005-02-01]. http://iopscience.iop.org/article/10.1088/0953-2048/18/4/001.

[16] QIAO Y, CHEN Y, XIONG X, et al. Scale up of coated conductor substrate process by reel-to-reel planarization of amorphous oxide layers[J]. IEEE Transactions on Applied Superconductivity, 2011, 21(3): 3055-3058. doi: 10.1109/TASC.2010.2082472

[17] CHU J, ZHAO Y, LIU L, et al. Topography evolution of rough-surface metallic substrates by solution deposition planarization method[J]. Applied Surface Science, 2018, 427(Part B): 237-242. http://smartsearch.nstl.gov.cn/paper_detail.html?id=ac4658e375f997c3b28d2232302d4979

[18] GUO P, XIONG J, CHEN Y, et al. Strong pinning in YBa2Cu3O7-δ, films with SDP-derived amorphous C layers[J]. Physica C Superconductivity & Its Applications, 2014, 507: 31-34. http://www.sciencedirect.com/science/article/pii/S0921453414003037

[19] 程崛. 溶液沉积平整化法优化金属基带表面平整度的工艺研究[D]. 成都: 电子科技大学, 2013. CHENG J. Study on the technology of solution deposition flatness method for optimizing surface flatness of metal baseband[D]. Chengdu: University of Electronic Science and Technology, 2013. (in Chinese)

[20] 杨科. 化学溶液法制备非晶Y2O3薄膜的研究[D]. 成都: 电子科技大学, 2014. YANG K. Study on amorphous Y2O3 thin films prepared by chemical solution method[D]. Chengdu: University of Electronic Science and Technology, 2014. (in Chinese)

[21] 翁文剑, 杨辉. 醋酸钇的溶胶-凝胶过程[C]//全国溶胶-凝胶科学技术学术会议. 大连: 中国硅酸盐学会, 1997: 55-58. WENG W J, YANG H. Sol-gel process of yttrium acetate[C]//Dalian: National Sol-Gel Science and Technology Conference. 1997: 55-58. (in Chinese)

[22] MARTYNOVA I, TSYMBARENKO D, KAMENEV A, et al. Synthesis and characterization of amorphous yttrium oxide layers by metal organic chemical solution deposition[J]. Physica E: Low-dimensional Systems and Nanostructures, 2014, 56: 447-451. doi: 10.1016/j.physe.2013.02.017

下载:

下载: