Preparation and Thermal Shock Performance of Solution Precursor Plasma Spraying La2Ce2O7 Thermal Barrier

-

摘要:

为了解决目前航空涡轮发动机使用温度低的问题,采用溶液等离子喷涂(solution precursor plasma spray,SPPS)方法制备铈酸镧(La2Ce2O7,LCO)热障涂层,分析探索了SPPS技术中喷涂距离、雾化气压力和前驱体浓度对LCO热障涂层的显微结构和热障性能的影响.研究结果表明:当喷涂距离达到设备极限距离35 mm、雾化气压力为100 kPa、前驱体浓度为0.4 mol/L时,涂层的熔化状态较佳,结构致密,孔隙分布均匀,垂直裂纹结构明显.SPPS法制备的LCO涂层的热循环寿命达60次,涂层热循环寿命的提高得益于涂层中特有的垂直裂纹结构,垂直裂纹的存在提升了涂层的应变容限,有效缓解了涂层的内应力.

Abstract:To solve the problem of low temperature in current aero-turbine engines, La2Ce2O7 (LCO) thermal barrier coating was prepared by using solution precursor plasma spray (SPPS) with new thermal barrier coating materials, and the influence of spraying distance, atomized air pressure and precursor concentration in SPPS technology on the microstructure and performance of LCO thermal barrier coating was analyzed. Results show that when the spraying distance reaches 35mm, the pressure of atomized gas is 100 kPa, and the precursor concentration is 0.4 mol/L, the melting state of the coating is better, with compact structure, uniform pore distribution and obvious vertical crack structure. The thermal cycle life of LCO coating prepared by SPPS method reaches 60 times. The improvement is due to the segmentation cracks in the coatings that improve the strain tolerance and effectively relieve the internal stress.

-

热障涂层(thermal barrier coatings,TBCs)是先进航空发动机燃气涡轮叶片的三大关键技术之一.目前使用的热障涂层陶瓷隔热层材料为氧化钇稳定的氧化锆(yttria-stabilised zirconia,YSZ),其长期使用温度不能超过1 200 ℃,难以作为下一代高性能航空发动机的热障涂层材料[1-3].铈酸镧(La2Ce2O7,LCO)由于具有非常高的热结构稳定性和较低的热导率[4-6],从繁多的候选材料中脱颖而出.

溶液等离子喷涂(solution precursor plasma spray,SPPS)是一种制备纳米涂层的热喷涂技术.与等离子喷涂(atmospheric plasma spray,APS)相比,SPPS是在APS的基础上将固体粉末送料改为液料,将原料前驱体雾化后注入到等离子焰流中喷涂到样品表面形成涂层,这就很好地解决了LCO纳米粉末输送难和晶粒长大等问题[7-8].美国纽约州立大学的Karthikeyan等[9]首先提出用溶液等离子喷涂法合成纳米粉末和纳米涂层,并对其沉积机理进行初步探索.纽约州立大学实验室最早尝试将金属无机盐或有机盐溶液注入等离子火焰中制备纳米涂层[10]. Bernard等[11]采用悬浮液等离子喷涂成功制备出YSZ热障涂层,涂层具有柱状晶结构,同时对柱状晶的形成机理进行了初步的研究.国内较早开展溶液等离子喷涂研究的有武汉理工大学的王晋春[12]、闵捷[13]、程旭东等[14],他们以溶胶前驱体制备出纳米尺寸的YSZ热障涂层,涂层无层间裂纹,热循环性能优于APS所制备的热障涂层,同时对溶胶的形成机理进行了深入探究.

本实验为解决下一代航空发动机La系热障涂层材料热循环寿命低的问题,采用SPPS技术制备纳米LCO涂层.通过LCO溶液前驱体的配制、喷涂工艺参数的优化及热震性能的评价等,为La系热障涂层的设计、服役和溶液等离子喷涂的实际应用提供参考依据.

1. 实验

1.1 实验材料

本实验以六水硝酸铈(Ce(NO3)3·6H2O)和六水硝酸镧(La(NO3)3·6H2O)作为溶质,去离子水作为溶剂,利用Ce(NO3)3·6H2O和La(NO3)3·6H2O在水中的水解作用,通过滴加氨水作为水解的促进剂,生成Ce(OH)3与La(OH)3微粒.在等离子喷涂过程中,由于CeO2的饱和蒸气压远高于La2O3的饱和蒸气压,因此在高温等离子火焰下CeO2的损失量要多于La2O3的损失量.所以在溶液配制阶段需要提高硝酸铈的比例.根据前期大气等离子喷涂实验CeO2挥发量的结果[11],CeO2的挥发量约为16%,后续的溶液配制中均以n(La):n(Ce)=1.00:1.16的比例进行配制.

1.2 涂层制备

本实验中基底材料为Inconel 718高温合金(上海钢浩有色金属有限公司),黏结层材料为NiCoCrAlY合金粉末(清河县安迪金属材料有限公司).喷涂实验采用瑞士MC60等离子喷涂设备及自行设计的液相送料系统.喷涂功率选用最大功率45 kW, Ar和H2分别为主气和辅气,N2作为溶液喷涂的雾化气体,基体喷涂前预热到500 ℃.

1.3 涂层性能的表征

涂层试样采用德国Bruker Advanced D-8 X射线衍射仪(X-ray diffraction, XRD)进行物相检测.涂层的形貌采用美国FEI公司QUANTA-450型扫描电子显微镜进行测试分析.溶液的pH采用上海雷磁PHS-25型酸度计进行测试分析.黏度采用沈阳兴亚平式黏度计进行测试分析.按照航空工业标准(HB7269—96)进行涂层热震性能测试[15],将制备好的涂层试样(ϕ25.4 mm)放入电阻炉中,随炉快速升温至1 100 ℃后保温5 min;随后将保温的试样取出并迅速投入到20 ℃±5 ℃的水中淬冷,至室温后取出,观察试样表面破坏情况,该过程即为一次热循环;重复该实验过程,直至试样涂层表面脱落面积达到整个涂层面积的5%即为失效.

2. 结果和讨论

2.1 LC溶液前驱体的制备

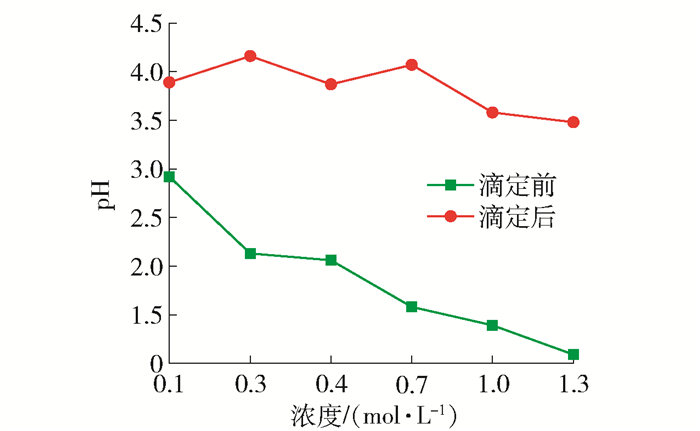

采用共沉淀法制备溶液前驱体,硝酸铈(Ce(NO3)3·6H2O)和硝酸镧(La(NO3)3·6H2O)在溶于水后形成Ce3+、La3+和NO3-,Ce3+和La3+的水解使溶液呈酸性,水解产生的Ce(OH)3与La(OH)3微粒分散于溶液中,对pH的调节可以促进Ce3+和La3+的水解,加速产生更多Ce(OH)3与La(OH)3微粒.在保持溶液澄清透明状态下,Ce(OH)3与La(OH)3微粒越多越有利于后续的等离子喷涂.在滴定氨水的过程中,随着氨水的加入,溶液的pH在增加,Ce3+和La3+的水解程度增大,此时Ce(OH)3与La(OH)3微粒也在不断增加. pH通过影响溶液中水解和缩聚的程度控制胶粒的形核与长大,随着溶液pH的增大,Ce3+和La3+水解产生的H+与氨水提供的OH-发生中和反应,进而促进Ce3+和La3+的水解,微粒数目急剧增加,微粒之间不断发生聚合作用,导致微粒尺寸变大,当pH过高溶液会析出大量沉淀,沉淀的产生对后续送料将产生不利影响,因此溶液的pH不宜过高,应调节至3~5才能保持溶液的稳定性,如表 1所示.由图 1可知,滴定后溶液浓度越高,对应的pH越低,且溶液pH均在3以下,溶液此时呈强酸性. pH在3~5的溶液前驱体能保证长时间稳定输送,从稳定性和可输送性方面可以满足溶液前驱体性能的要求.

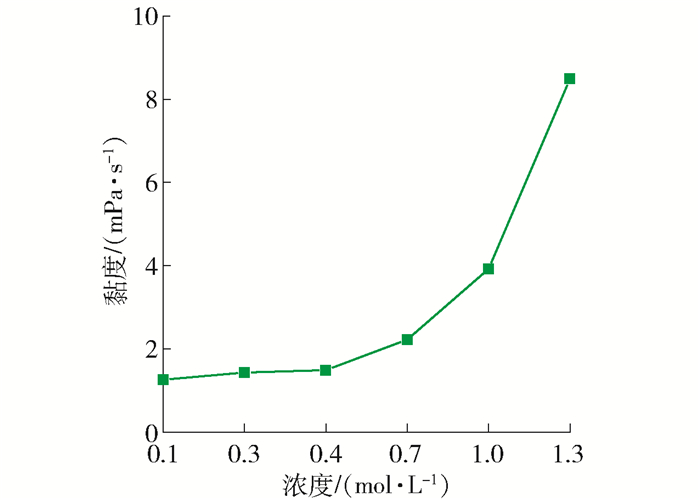

表 1 不同pH下溶液前驱体性能对比Table 1. Comparison of solution precursor performance at different pH valuespH 稳定性 存在状态 可输送性 3~5 长时间 透明溶液 好 6~7 ~12 h 少量白色胶状沉淀 可以输送 8~10 ~6 h 白色溶胶 难以输送 图 2为溶液浓度与黏度的关系,其中溶液pH均在4左右,溶液浓度越高,随之黏度越大,黏度过大一般会影响后续送料的稳定性,但所配制的溶液黏度均在10 mPa/s以下,溶液等离子喷涂中溶液黏度小于10 mPa/s均能够快速稳定地送入等离子火焰中,满足使用的要求[4].

溶液前驱体的固含量是溶液烘干后干物质质量与原溶液质量的比值,如

$$ 固含量\frac{{烘干后物质质量}}{{原溶液质量}} $$ (1) 所示.本文对实验中所配制的溶液前驱体固含量进行了分析,实验结果如表 2所示.从表 2可看出,固含量随着浓度的提高而增加,浓度最高的前驱体的固含量达44.9%,前后相差近5倍,固含量对涂层的沉积效率影响较大,高的溶液固含量可以显著提升涂层的沉积效率.

表 2 不同浓度前驱体固含量结果Table 2. Solid concentration results of different concentrations of precursors浓度/(mol·L-1) 0.1 0.4 0.7 1.0 固含量/% 8.23 26.49 38.52 44.92 2.2 LC热障涂层喷涂工艺的研究

SPPS整个喷涂过程涉及十分复杂的化学和物理变化.影响涂层结构最主要的工艺参数为功率、喷涂的距离、雾化气压力以及溶液浓度,在溶液等离子喷涂过程中除喷涂功率外,喷涂距离对于制备出结构良好的涂层最为重要,其次是雾化气压力以及溶液浓度[16].根据前期实验结果,采用高工作功率、基体预加热的热喷涂条件可以获得具有垂直裂纹结构的热障涂层,垂直裂纹结构可以提升涂层的应变容限,有效缓解涂层中的内应力[4],因此选用设备最大功率45 kW.

2.2.1 喷涂距离对涂层结构的影响

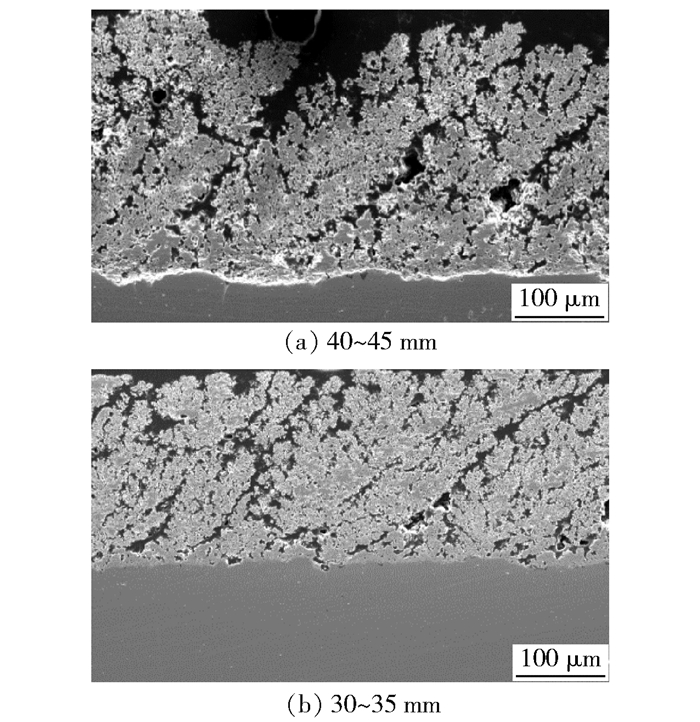

当喷涂距离为40~45 mm时,所制备的涂层存在较多缺陷与孔洞,部分区域呈现羽毛状,涂层表面参差不齐,结构较为疏松,如图 3(a)所示;当降低喷涂距离至30~35 mm时,制备出的涂层致密度有了较大提高,涂层的缺陷减少,孔隙分布均匀且涂层中没有出现传统涂层的层状结构,具有垂直裂纹结构,如图 3(b)所示.本实验中30 mm的喷涂距离已是设备的极限,因此喷涂距离选定30~35 mm.

2.2.2 雾化气压力对涂层结构的影响

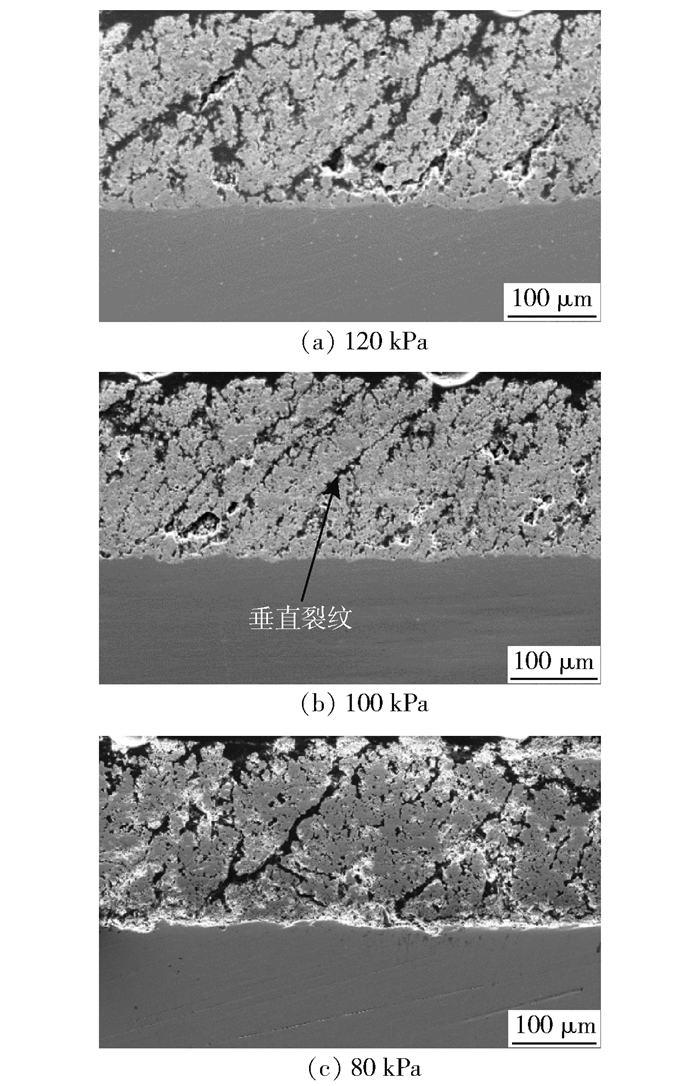

雾化气压力对涂层的孔洞以及孔隙尺寸存在较大影响[15],图 4所示为选用喷涂距离为30~35 mm时不同雾化气压力下制备的LCO热障涂层截面形貌.雾化气压力为120 kPa时,所制备的涂层如图 4(a)所示,涂层中存在较多缺陷,在孔隙周围分布有较大的孔洞.降低雾化气压力至100 kPa,分布于孔隙周围的大尺寸孔洞数目明显减少,涂层质量有较大提升,如图 4(b)所示.进一步降低雾化气压力为80 kPa时,涂层中缺陷增加且涂层的致密度升高,涂层表层平整度较差,如图 4(c)所示.

在SPPS工艺中,溶液前驱体通过二流气雾化喷嘴雾化、加速后沉积在基体上.雾化气压力提高.一方面,雾化后溶液前驱体液滴更细、速度更高,部分溶液前驱体穿过等离子射流中心;另一方面,雾化射流对等离子射流冲击更大,使等离子射流变形严重,同时降低了等离子射流能量密度,反应不完全的溶液前驱体所占比例升高,涂层中大尺寸孔洞所占比例升高.雾化气压力降低,雾化后溶液前驱体液滴相对较大,在等离子火焰中经历一系列物理化学变化,最终形成熔融态的液体颗粒沉积到基底上.一方面,由于尺寸相对较大,动能较高,撞击在基底上形成较为致密的涂层;另一方面,较大的颗粒导致涂层在冷却过程中形成的孔隙尺寸较大,从而影响涂层质量.因此雾化气压力选定100 kPa.

2.2.3 前驱体浓度对涂层结构的影响

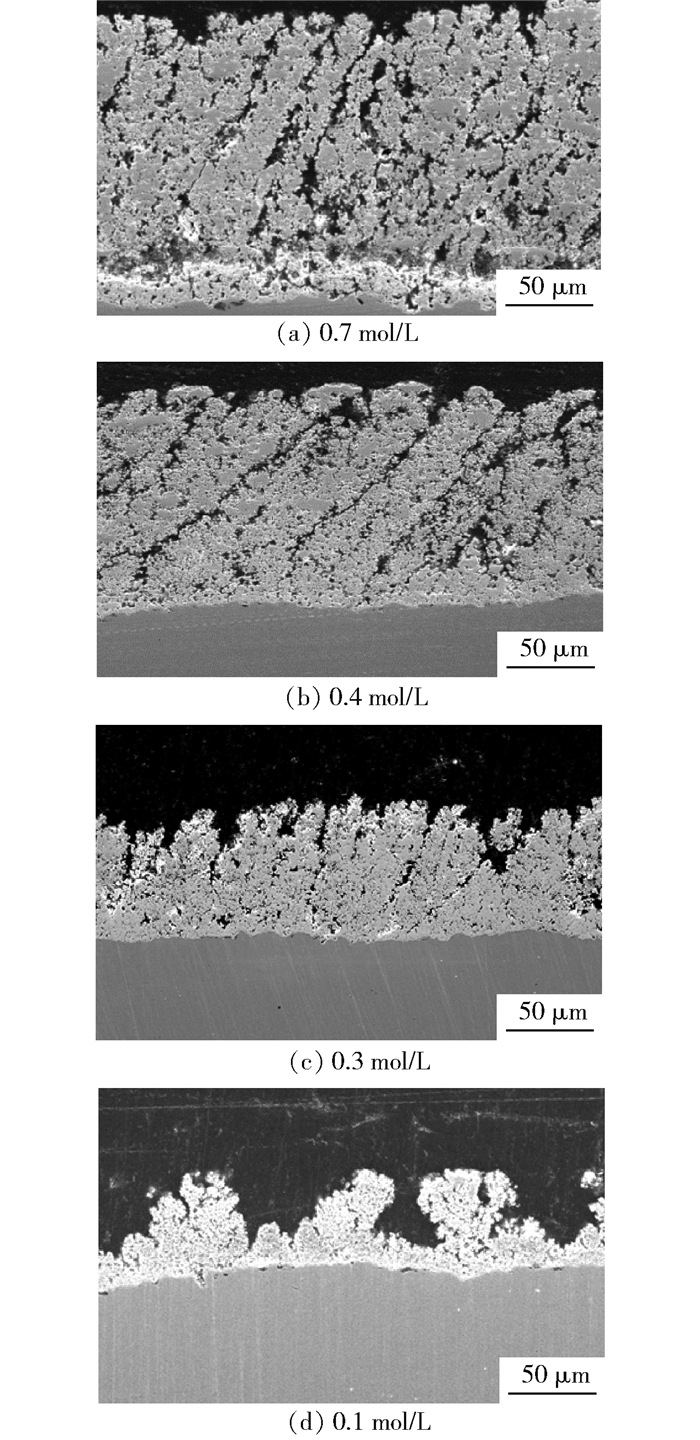

如图 5所示为选用喷涂距离为30~35 mm和雾化气压力100 kPa时不同浓度前驱体制备的LCO热障涂层截面形貌. 图 5(a)为浓度0.7 mol/L的LCO溶液前驱体制备的LCO涂层,涂层中存在大小不一的孔洞,其间出现类似垂直裂纹结构,但垂直裂纹密度低,在裂纹附近的孔洞尺寸较大,涂层中未见到传统APS涂层的层状结构.当溶液浓度调整为0.4 mol/L时,涂层致密度进一步提高,厚度均匀且颗粒融化较好,孔隙均匀且细小,垂直裂纹结构明显,如图 5(b)所示.溶液浓度为0.3 mol/L制备的涂层如图 5(c)所示,涂层表面参差不齐,接近涂层表面的区域有较多孔隙且涂层相对较薄. 图 5(d)为溶液浓度0.1 mol/L所制备的涂层,涂层非常薄,表面高低起伏,颗粒融化不均匀且涂层质量较差[17].

2.3 涂层性能的表征

2.3.1 涂层的物相分析

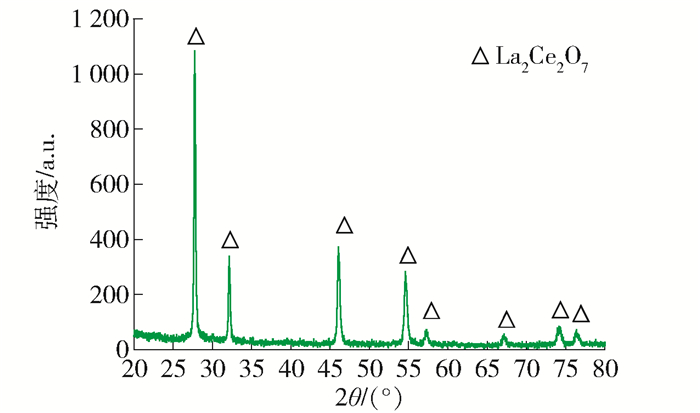

图 6为图 5(b)制备的LCO热障涂层的XRD图谱,可以看出LCO涂层具有萤石结构,衍射峰尖锐且强度高;同时图谱中未发现La2O3的峰,说明La2O3很好地固溶到CeO2的间隙中,形成萤石结构的相. 表 3为图 5(b)制备的LCO热障涂层的能谱分析结果,涂层中镧和铈的物质的量比接近于1:1,因此通过调整原始溶液中镧和铈的比例(n(La):n(Ce)=1.00:1.16),可以有效地解决CeO2的挥发所带来的问题.

表 3 LCO热障涂层元素比例Table 3. Element ratio of LCO thermal barrier coating元素 w/% x/% O 15.08 60.77 La 42.46 19.70 Ce 42.45 19.53 2.3.2 涂层的抗热震性能

涂层的抗热震性能与涂层的服役寿命有着极为紧密的联系.涂层抗热震性能的好坏除了涂层材料本身的特性外还与喷涂工艺、涂层结构以及服役环境有关.采用设备最大功率为45 kW,喷涂距离为35 mm,雾化气压力为100 kPa,溶液浓度为0.4 mol/L,制备了厚度约180 μm的LCO热障涂层. SPPS法制备的涂层热循环寿命得到了显著的提升,最高可达到60次,而传统APS法制备的LCO涂层热循环寿命一般在20次左右[18-19].涂层热循环寿命的提升得益于涂层中特有的垂直裂纹结构,垂直裂纹提升了涂层的应变容限,有效缓解涂层中的内应力,同时纳米结构的SPPS涂层在热循环应力作用下,纳米晶粒能够发生滑动或转动,该过程能够有效释放应力,降低陶瓷层的脆性,进一步提升涂层的热循环寿命.

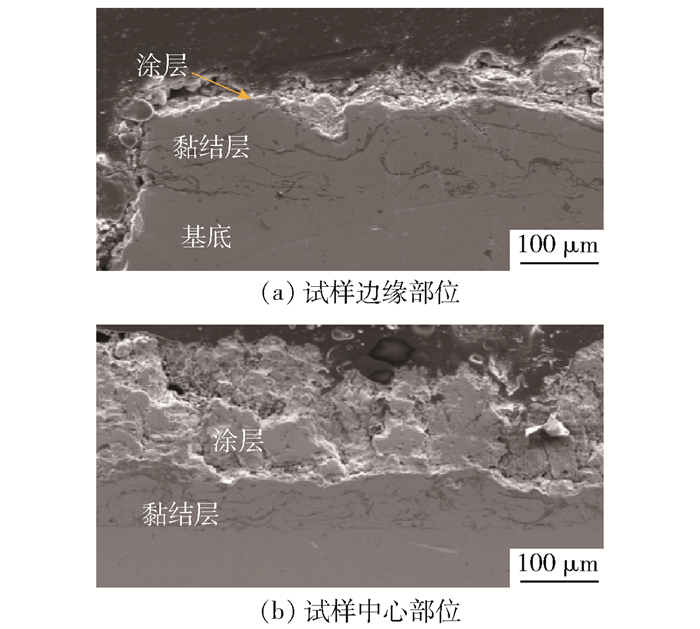

图 7为试样60次热循环后截面形貌,涂层中未出现热生长氧化物(thermal growth oxide,TGO),因此涂层的脱落并不是TGO所引起的.试样之所以主要从边缘脱落,一方面是由于边缘效应造成应力集中,另一方面可能是由于边缘处LCO较薄,没有充分缓解由于LCO与黏结层热膨胀不匹配产生的应力.试样中间区域的陶瓷涂层脱落形式与边缘脱落不一样,试样中心区域的涂层存在逐层脱落的迹象,同时试样比之前致密了很多,这可能是试样在热震过程中,LCO涂层表面温度要高于内部温度,在高温下LCO涂层表面发生烧结现象,导致涂层发生横向收缩,当烧结达到一定程度,由于张应力的增加会在陶瓷层中产生横向微裂纹,导致涂层出现逐层脱落;另外,涂层在低氧分压下会产生部分氧孔穴,并发生微小收缩[20],在涂层的热循环过程中,由于CeO2发生微弱的热分解可能会失去微量氧,加剧涂层的脱落.

3. 结论

1) 采用共沉淀法制备的LCO前驱体固含量为26.49%,pH为3~5,黏度值小于10 mPa/s,保证喷涂过程中长时间的稳定输送,可以满足溶液等离子喷涂的要求.

2) 喷涂参数中喷涂距离对涂层结构影响最为关键,喷涂距离影响涂层沉积形态,当喷涂距离达到设备极限距离35 mm时,涂层的结构最为紧密,粒子获得的动能最大,大部分铺展在基底上,结合良好;雾化气压力对涂层孔隙大小有很大影响,当雾化气压力为100 kPa时,涂层的孔隙最为细小,分布均匀;溶液浓度为0.4 mol/L时涂层的熔化状态较佳,涂层结构致密,孔隙分布均匀,垂直裂纹结构明显.

3) 热震循环结果表明:SPPS制备的LCO涂层的热循环寿命达60次,优于APS制备的LCO涂层,涂层中垂直裂纹的存在提升了热循环寿命.热循环后的涂层形貌显示涂层中未出现热生长氧化物,涂层的逐层脱落是由于高温下LCO表面发生烧结,CeO2发生微弱的热分解失去微量氧造成的.

-

表 1 不同pH下溶液前驱体性能对比

Table 1 Comparison of solution precursor performance at different pH values

pH 稳定性 存在状态 可输送性 3~5 长时间 透明溶液 好 6~7 ~12 h 少量白色胶状沉淀 可以输送 8~10 ~6 h 白色溶胶 难以输送 表 2 不同浓度前驱体固含量结果

Table 2 Solid concentration results of different concentrations of precursors

浓度/(mol·L-1) 0.1 0.4 0.7 1.0 固含量/% 8.23 26.49 38.52 44.92 表 3 LCO热障涂层元素比例

Table 3 Element ratio of LCO thermal barrier coating

元素 w/% x/% O 15.08 60.77 La 42.46 19.70 Ce 42.45 19.53 -

[1] ZHAO J C, WESTBROOK J H. Ultra high temperature materials for jet engines[J]. MRS Bulletin, 2003, 9:622-630.

[2] 耿欣, 李大玉, 张超.液料等离子喷涂制备功能涂层的研究进展[J].化工新型材料, 2016(4):26-28. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxxcl201604009 GENG X, LI D Y, ZHANG C. Research progress of functional coating deposited by liquid plasma spraying[J]. New Chemical Materials, 2016(4):26-28. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxxcl201604009

[3] 郝维维, 郑蕾, 郭洪波, 等.等离子喷涂LaTi2Al9O19热障涂层的微观组织结构及热物理性能[J].航空学报, 2013, 34(6):1485-1492. http://d.old.wanfangdata.com.cn/Periodical/hkxb201306028 HAO W W, ZHENG L, GUO H B, et al. Microstructure and thermo-physical properties of plasma sprayed LaTi2A19O19 thermal barrier coatings[J]. Acta Aeronautica ET Astronautica Sinica, 2013, 34(6):1485-1492. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkxb201306028

[4] 马文, 郭洪波, 宫声凯, 等.等离子喷涂铈酸镧热障涂层[J].无机材料学报, 2009, 24(5):983-988. http://d.old.wanfangdata.com.cn/Periodical/wjclxb200905022 MA W, GUO H B, GONG S K, et al. Lanthanum-cerium oxide thermal barrier coatings prepared by atmospheric plasma spraying[J]. Journal of Inorganic Materials, 2009, 24(5):983-988. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/wjclxb200905022

[5] WANG Y, COYLE T W. Solution precursor plasma spray of nickel-yittia stabilized zirconia anodes for solid oxide fuel cell application[J]. Journal of Thermal Spray Technology, 2007, 16(5):898-904. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=05c6314cc68f2b813d8cf7583588a890

[6] DONG H, WANG D, PEI Y, et al. Optimization and thermal cycling behavior of La2Ce2O7 thermal barrier coatings[J]. Ceramics International, 2013, 39(2):1863-1870. doi: 10.1016/j.ceramint.2012.08.034

[7] 曹学强.热障涂层材料[J].功能材料信息, 2007(5):57-58. http://d.old.wanfangdata.com.cn/Periodical/hkxb200001002 CAO X Q. Thermal barrier coating[J]. Functional Materials Information, 2007(5):57-58. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkxb200001002

[8] 周洪, 李飞, 何博, 等.热障涂层材料研究进展[J].材料导报, 1994, 20(10):40-43. http://d.old.wanfangdata.com.cn/Periodical/cldb200610011 ZHOU H, LI F, HE B, et al. Research progresses in materials for thermal barrier coatings[J]. Materials Review, 1994, 20(10):40-43. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/cldb200610011

[9] KARTHIKEYAN J, BERNDT C C, TIKKANEN J, et al. Plasma spray synthesis of nanomaterial powders and deposits[J]. Materials Science & Engineering A, 1997, 238(2):275-286. http://cn.bing.com/academic/profile?id=4ae710421fddbae7d590d38cdccc1333&encoded=0&v=paper_preview&mkt=zh-cn

[10] FAUCHAIS P, MONTAVON G. Latest developments in suspension and liquid precursor thermal spraying[J]. Journal of Thermal Spray Technology, 2010, 19(1/2):226-239. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=17a1504e5d4e2f01d22fa958ea0d467a

[11] BERNARD B, BIANCHI L, MALIE A, et al. Columnar suspension plasma sprayed coating microstructural control for thermal barrier coating application[J]. Journal of the European Ceramic Society, 2016, 36(4):1081-1089. doi: 10.1016/j.jeurceramsoc.2015.11.018

[12] 王晋春.液相等离子喷涂纳米ZrO2/Y2O3涂层的制备、结构和性能研究[D].武汉: 武汉理工大学, 2006. WANG J C. Study on preparation, structure and properties of nanostructured ZrO2/Y2O3 coatings prepared by solution precursor plasma spray[D]. Wuhan: Wuhan University of Technology, 2006. (in Chinese)

[13] 闵捷.液料等离子喷涂纳米氧化锆/氧化钇涂层的结构与性能研究[D].武汉: 武汉理工大学, 2010. MIN J. Study on structure and properities of solution plasma spray nano-ZrO2/Y2O3 coatings[D]. Wuhan: Wuhan University of Technology, 2010. (in Chinese)

[14] 程旭东, 王晋春, 李丹虹, 等.液相等离子喷涂制备纳米ZrO2/Y2O3涂层的研究[J].材料保护, 2006, 39(6):1-4. doi: 10.3969/j.issn.1001-1560.2006.06.001 CHENG X D, WANG J C, LI D H, et al. Microstructure and thermal-shocking resistance of nanostructured zirconia coating prepared by solution precursor plasma spraying[J]. Journal of Materials Protection, 2006, 39(6):1-4. (in Chinese) doi: 10.3969/j.issn.1001-1560.2006.06.001

[15] 梁波, 丁传贤.氧化锆纳米等离子涂层的结构与热震性能研究[J].无机材料学报, 2006, 21(1):250-256. doi: 10.3321/j.issn:1000-324X.2006.01.042 LIANG B, DING C X. Microstructure of nanostructureed coating and its thermal shock resistance[J]. Journal of Inorganic Materials, 2006, 21(1):250-256. (in Chinese) doi: 10.3321/j.issn:1000-324X.2006.01.042

[16] GOVINDARAJAN S, DUSANE R O, JOSHI S V. In situ particle generation and splat formation during solution precursor plasma spraying of yttria-stabilized zirconia coatings[J]. Journal of the American Ceramic Society, 2011, 94(12):4191-4199. doi: 10.1111/j.1551-2916.2011.04773.x

[17] CHEN D, JORDAN E H, GELL M. Effect of solution concentration on splat formation and coating microstructure using the solution precursor plasma spray process[J]. Surface & Coatings Technology, 2008, 202(10):2132-2138. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ccd6cf7a8571d458f69a78928d17c0b1

[18] WANG Y, GUO H B, LI Z Y, et al. Segmented lanthanum cerium oxide thermal barrier coatings by atmospheric plasma spray[J]. Surface Engineering, 2009, 25(7):555-558. doi: 10.1179/174329409X409503

[19] WANG Y, LI M X, SUO H L. Mechanical properties of YSZ thermal barrier coatings with segmented structure[J]. Surface Engineering, 2012, 28(5):329-332. doi: 10.1179/1743294412Y.0000000006

[20] KWASAKI A, WATANABE R. Cyclic thermal fracture behavior and spallation life of PSZ/NiCrAlY functionally graded thermal barrier coatings[J]. Materials Science Forum, 1999, 308/309/310/311(1):402-409. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/MSF.308-311.402

-

期刊类型引用(12)

1. 田英良,赵志龙,赵志永. 新型显示用玻璃材料发展回顾及展望. 科技导报. 2025(02): 90-96 .  百度学术

百度学术

2. 高强,刘振英,彭小波,石丽芬,周刚,周俊,陈仕威. 化学强化工艺对3~6 mm厚锂铝硅玻璃的抗冲击性能影响. 硅酸盐通报. 2024(12): 4578-4587 .  百度学术

百度学术

3. 陈福,夏韦美,续芯如,陈兆民,张天英. 锂铝硅玻璃. 玻璃. 2023(04): 10-14 .  百度学术

百度学术

4. 马赫,梁荻,曹生硕,陈雪梅,胡悫睿,胡斌,匡波. La_2O_3和Y_2O_3对高铝盖板玻璃结构及性能的影响. 玻璃搪瓷与眼镜. 2023(06): 7-15+42 .  百度学术

百度学术

5. 陈招娣. 锂铝硅玻璃对锆英石溢流砖的侵蚀性研究. 玻璃搪瓷与眼镜. 2023(08): 1-6+28 .  百度学术

百度学术

6. 刘红刚,平文亮,李升,康庆伟,陈健濠,肖子凡,董国平. 碱金属和碱土金属铝硅酸盐微晶盖板玻璃的研究现状和发展趋势. 硅酸盐通报. 2022(11): 3925-3936 .  百度学术

百度学术

7. 田英良,陈鑫鑫,蔡礼貌,李彦涛,李聚锋,刘亚茹,王伟来. 碱土金属氧化物及氧化还原值对低铝玻璃表面渗锡的影响. 北京工业大学学报. 2021(01): 70-75 .  本站查看

本站查看

8. 司敏杰,郭卫,田芳,张飞龙,李兵,马小营. 超薄盖板玻璃二步法离子强化工艺研究进展. 玻璃. 2021(02): 13-17 .  百度学术

百度学术

9. 王明忠,梁新辉,宋占财,钟波,崔秀珍,韩建军,刘超,谢俊. 锂铝硅酸盐玻璃的化学强化工艺参数研究. 玻璃搪瓷与眼镜. 2021(02): 18-22 .  百度学术

百度学术

10. 王明忠,何进,钟波,崔秀珍,梁新辉. 高碱铝硅玻璃浮法熔窑用耐火材料的侵蚀研究. 玻璃搪瓷与眼镜. 2021(10): 17-22+10 .  百度学术

百度学术

11. 田英良,李俊杰,宫汝华,胡伟. 碱铝硅酸盐玻璃化学强化关键影响因素概述(续). 玻璃搪瓷与眼镜. 2020(03): 24-29 .  百度学术

百度学术

12. 王明忠,梁新辉,宋占财,陆平. 熔盐配比对锂铝硅玻璃化学强化性能的影响. 玻璃搪瓷与眼镜. 2020(06): 8-12 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: