Numerical Study of Leakage Characteristics of Organic Fluids in Single Screw Expander

-

摘要:

为了研究单螺杆膨胀机内泄漏特性,建立单螺杆膨胀机热力学工作过程的数学模型和油气混合的两相泄漏模型,分析间隙高度对各泄漏通道泄漏量的影响,并比较3种有机工质R123、R134a、R245fa在不同转速和进气压力下对单螺杆膨胀机容积效率和泄漏量的影响.结果表明,9条泄漏通道中,螺杆与壳体之间的泄漏量占主要部分,其次是星轮与螺槽之间的泄漏量,星轮与壳体之间的泄漏量较小.增加转速和进气压力均可增大单螺杆膨胀机的容积效率.在相同的工况条件下,以R123为工质的单螺杆膨胀机容积利用率最高,其次是R245fa,R134a最低.

Abstract:In order to investigate the internal leakage characteristics of the expander, a mathematical model of the thermodynamic working process and a two-phase leakage model for gas-oil flow were established. The influence of clearance height on the leakage path of different leakage path was analyzed, and the influence of rotational speed and inlet pressure on the volumetric efficiency and leakage flow rate under three organic fluids (i.e. R123, R134 and R245fa) was compared. The results show that the leakage through the clearance gap between screw rotor and shell accounts for the most part, followed by the leakage through the clearance gap between screw groove and gate rotor, and the leakage through the clearance gap between gate rotor and shell is relatively small. The volumetric efficiency increases with the rotational speed and the inlet pressure. The volumetric efficiency of the single screw expander using the R123 as the working fluid is the best under the same working conditions, followed by R245fa and R134a.

-

Keywords:

- single screw expander /

- leakage rate /

- volumetric efficiency /

- organic fluids /

- numerical study

-

随着我国能源危机和环境问题的日益严峻,可再生能源和各种节能技术的研究与应用受到广泛地关注.在各种节能技术中,工业余能的回收利用是重要的技术领域.其中,有机朗肯循环的低温工业余热回收发电技术得到了高度重视和广泛研究[1-3].单螺杆膨胀机作为一种新型的容积式膨胀机,具有膨胀比高、受力平衡、振动小、噪音低、寿命长、容积效率高和适用压力范围广等多方面的优势[4],有望在有机朗肯循环的低温热能发电系统获得应用,为节能环保贡献力量.

目前,国内外学者对单螺杆膨胀机进行了一些性能分析和实验研究. Gusev等[5]分析了单螺杆膨胀机有机朗肯循环与热源温度和质量流量的关系,对常用于低温余热回收利用的两种有机工质Solkatherm和R245fa进行了测试. Ziviani等[6]对单螺杆膨胀机进行了理论分析计算和实验研究,实验测得转速在3 000 r/min时,绝热效率最大可达到67%,理论模型与实验结果的质量流率和输出功率的误差分布在10%和15%以内. Desideri等[7]以Solkatherm为工质,对基于有机朗肯循环的单螺杆膨胀机进行了性能测试,测得膨胀机最大等熵效率和功率分别为64.78%和7.8 kW.北京工业大学传热强化与过程节能教育部重点实验室开展单螺杆膨胀机的研发和制造,并开展了一些单螺杆膨胀机性能方面的理论分析和实验研究[8-14].然而,在单螺杆膨胀机实际的工作过程中,存在多种不可逆损失,其中,气体泄漏损失对机器的性能影响非常大.目前,虽然已经开展了单螺杆膨胀机的相关研究,但都不能直接反映泄漏对膨胀机性能的影响.

由于单螺杆压缩机与单螺杆膨胀机具有结构的相似性,前者内泄漏特性已经得到了较为详细的研究,Bein等[15]和Boblitt等[16]将一维绝热喷管模型和达西公式分别用于计算单螺杆压缩机气体和油的泄漏量.西安交通大学的研究者们[17-19]从单螺杆压缩机的结构出发,建立各个泄漏通道的理论泄漏模型,分析泄漏对压缩机性能的影响,并通过实验进行验证. Wang等[20]详细地研究了多列圆柱包络的单螺杆制冷压缩机泄漏特性,建立了两相流的数学模型,并与直线包络的单螺杆压缩机泄漏进行了比较.然而,由于膨胀机和压缩机二者的实际工况相差很大,因此,单螺杆压缩机的泄漏模型并不能简单地应用于单螺杆膨胀机.

本文通过建立单螺杆膨胀机热力学工作过程的数学模型和泄漏模型,采用多次分离求解的思想,应用四阶龙格库塔法,并通过MATLAB软件求解该模型.分析间隙高度对各泄漏通道泄漏量的影响,并比较3种有机工质R123、R134a、R245fa在不同转速和进气压力下对单螺杆膨胀机容积效率和泄漏量的影响,为单螺杆膨胀机的性能优化提供理论指导.

1. 单螺杆膨胀机的基本结构

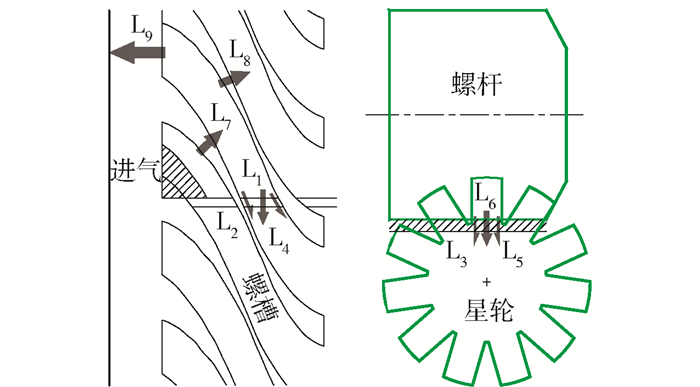

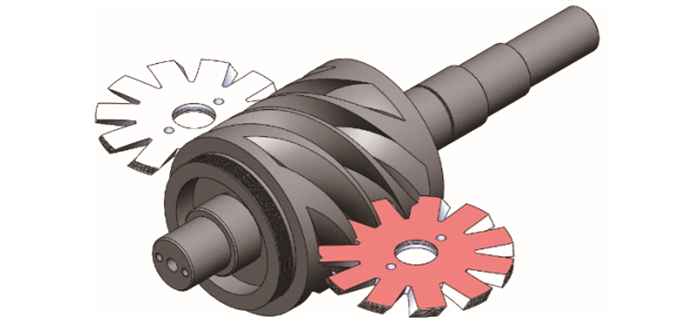

单螺杆膨胀机主要由螺杆转子、星轮、机壳、主轴以及轴承、轴封等零件构成.螺杆、星轮和机壳是单螺杆膨胀机的主要部件.目前,最常用的是CP型,CP型单螺杆膨胀机由1个圆柱螺杆和2个对称配置的平面星轮组成啮合副,如图 1所示.标准CP型单螺杆膨胀机为六螺槽结构,由2个星轮将各螺槽分隔成上、下2个空间,螺杆螺槽、机壳内壁和星轮齿顶面构成封闭的基元容积,按照一定的相位差实现周期性吸气、膨胀和排气过程[21].

螺杆螺槽、机壳内壁和星轮齿顶面构成封闭的基元容积,由于三者之间存在相对运动关系,因此,单螺杆膨胀机在工作过程中产生了9条泄漏通道[22],如图 2所示.星轮齿顶与螺槽底面之间的间隙为L1;星轮齿前、后侧与螺槽侧面之间的间隙为L2、L4;星轮齿前、后侧,螺槽侧面及壳体围成的径向泄漏孔为L3、L5;星轮平面与壳体内壁面之间的间隙为L6;螺槽前后侧外缘与壳体内壁面之间的间隙为L7、L8;螺槽进气端外缘与壳体内壁之间的间隙为L9.

2. 热力学工作过程的数学模型

2.1 模型假设

单螺杆膨胀机工作时,基元容积会通过泄漏通道与进气孔口、排气腔及其他螺槽的基元容积进行质量交换,因此,该工作过程为变质量系统的热力学过程.为了简化计算,需要忽略影响泄漏的次要因素,抓住主要因素.本文研究的基本假设有以下几点:

1) 各基元容积在相同的螺杆转子转角位置时,其内的工质状态参数均相同.

2) 气体在膨胀机内的流动均为绝热稳定流动,忽略气体的位能和动能,且工质与膨胀机螺杆、机体等壁面间没有热交换,油、气之间也无热交换.

3) 排气腔比基元容积大得多,且其内气体无脉动,将排气腔按无限大处理,等于名义排气压力.

2.2 热力学工作过程模型

根据以上基本假设,通过变质量系统的质量守恒方程、能量守恒,可以得出一组有关各热力学参数的基本微分方程组,它适用于膨胀机的各工作过程.通过热力学基本关系式化简得到基元容积内质量、压力和温度变化率方程为

$$ \frac{{{\rm{d}}m}}{{{\rm{d}}\theta }} = \frac{{{\rm{d}}{m_{{\rm{in}}}}}}{{{\rm{d}}\theta }} + \frac{{{\rm{d}}{m_{{\rm{out}}}}}}{{{\rm{d}}\theta }} $$ (1) $$ \begin{array}{l} \frac{{{\rm{d}}p}}{{{\rm{d}}\theta }} = \\ \frac{{\frac{1}{v}\left[ {{{\left( {\frac{{\partial h}}{{\partial v}}} \right)}_T} - \frac{{{{\left( {\partial h/\partial T} \right)}_v}{{\left( {\partial p/\partial v} \right)}_T}}}{{{{\left( {\partial p/\partial T} \right)}_v}}}} \right]\frac{{{\rm{d}}v}}{{{\rm{d}}\theta }} - \frac{1}{{{V_{\rm{c}}}}}\left[ {\sum {\frac{{{\rm{d}}{m_{{\rm{in}}}}}}{{{\rm{d}}\theta }}} ({h_{{\rm{in}}}} - h) - \frac{{{\rm{d}}Q}}{{{\rm{d}}\theta }}} \right]}}{{1 - \frac{1}{v}\frac{{{{\left( {\partial h/\partial T} \right)}_v}}}{{{{\left( {\partial p/\partial T} \right)}_v}}}}} \end{array} $$ (2) $$ \begin{array}{l} \frac{{{\rm{d}}T}}{{{\rm{d}}\theta }} = \\ \frac{{\frac{1}{v}\left[ {{{\left( {\frac{{\partial h}}{{\partial v}}} \right)}_T} - {{\left( {\frac{{\partial p}}{{\partial v}}} \right)}_T}} \right]\frac{{{\rm{d}}v}}{{{\rm{d}}\theta }} - \frac{1}{{{V_{\rm{c}}}}}\left[ {\sum {\frac{{{\rm{d}}{m_{{\rm{in}}}}}}{{{\rm{d}}\theta }}} ({h_{{\rm{in}}}} - h) - \frac{{{\rm{d}}Q}}{{{\rm{d}}\theta }}} \right]}}{{{{\left( {\frac{{\partial p}}{{\partial v}}} \right)}_v} - \frac{1}{v}{{\left( {\frac{{\partial h}}{{\partial T}}} \right)}_v}}} \end{array} $$ (3) 2.3 泄漏模型

单螺杆膨胀机内主要泄漏通道的长度及泄漏通道两壁面的曲率半径远远大于泄漏通道的间隙值,可看作是狭长形通道内润滑油和有机工质气体的油气混合物的层流流动[23],其质量流量的表达式为

$$ \frac{{{\rm{d}}{m_{{\rm{lea}}, i}}}}{{{\rm{d}}\theta }} = \alpha {A_i}{\rho _{\rm{g}}}{u_{\rm{g}}} $$ (4) $$ \frac{{{\rm{d}}{m_{{\rm{lea}}, 1}}}}{{{\rm{d}}\theta }} = \left( {1 - \alpha } \right){A_i}{\rho _{\rm{l}}}{u_{\rm{l}}} $$ (5) 其中,泄漏通道内气体和油的速度为

$$ {u_{\rm{g}}} = \sqrt {2({h_1} - {h_2})} $$ (6) $$ {u_{\rm{l}}} = {u_{\rm{g}}}/S $$ (7) 且滑移系数和空泡率的计算为

$$ S = 0.4 + 0.6\sqrt {\frac{{{\rho _{\rm{l}}}}}{{{\rho _{\rm{g}}}}} + 0.4\left( {\frac{1}{X} - 1} \right)} \sqrt {1 + 0.4\left( {\frac{1}{X} - 1} \right)} $$ (8) $$ \alpha = \frac{1}{{1 + S\left( {\frac{1}{X} - 1} \right)\frac{{{\rho _{\rm{g}}}}}{{{\rho _{\rm{l}}}}}}} $$ (9) 2.4 计算方法

单螺杆膨胀机基元容积内泄漏量的求解不仅与热力学工作过程参数密切相关,而且单螺杆膨胀机各个泄漏通道的泄漏均为实时进行,各通道之间也存在耦合关系.本文采用多次分离求解的思想,应用四阶龙格库塔法,并通过MATLAB仿真计算软件求解该复杂问题.即:假定初始工作过程无泄漏,求得的膨胀机热力学工作过程参数作为初值,以启动迭代,直至迭代收敛.迭代收敛后,分离解既能反映单螺杆膨胀机热力学工作过程参数对内泄漏的影响,又能反映泄漏对膨胀机热力学工作过程参数的影响.

2.5 容积效率

容积效率是评价容积式流体机械性能优劣的重要指标,反映膨胀机几何结构利用的完善程度.容积效率ηv是理论排气质量流量mt和实际排气质量流量mr的比值,即

$$ {\eta _{\rm{v}}} = \frac{{{m_{\rm{t}}}}}{{{m_{\rm{r}}}}} $$ (10) 理论排气质量流量可采用进气状态参数获得,模拟计算的实际排气质量流量由膨胀过程结束时螺槽内工质的质量决定,表示为

$$ {m_{\rm{t}}} = 2n{z_1}{V_{{\rm{in}}}}{\rho _{\rm{s}}} $$ (11) $$ {m_{\rm{r}}} = 2n{z_1}{m_{\rm{d}}} $$ (12) 式中:n为螺杆转速,r/min;z1为螺头数;Vin为螺槽的最大进气容积,m3;ρs为进气状态气体密度,kg/m3;md为膨胀终了基元容积内工质的质量.

3. 计算结果分析

3.1 模型验证

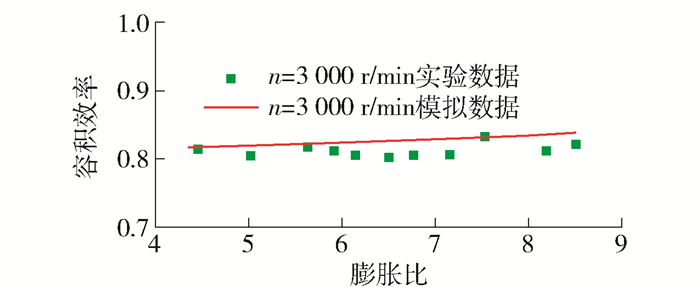

直接测量每个泄漏通道的泄漏量难度很大,通常可采用间接验证的方法来证明泄漏模型的可靠性和准确性.本文数值模拟计算所得的容积效率与文献[24]中给出的实验数据进行对比,单螺杆膨胀机的基本结构参数如表 1所示,有机工质为R123.当膨胀比(进气压力与排气压力的比值)在3.8~8.5范围内变化时,模拟计算的容积效率与实验值吻合较好,最大误差为2.14%,如图 3所示.因此,该泄漏模型可用于分析各参数对单螺杆膨胀机泄漏特性的影响.

表 1 单螺杆膨胀机基本结构参数Table 1. Basic structural parameters of single screw expander参数 数值 螺杆直径/mm 117 星轮直径/mm 117 中心矩/mm 93.6 星轮齿宽/mm 17.1 进气角/(°) 28.7 进气容积/dm3 0.010 2 内容积比 4.85 3.2 间隙高度

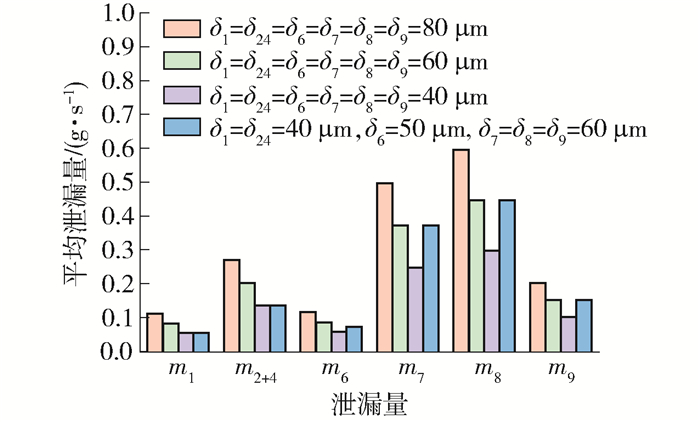

图 4给出工质R123在转速为3 000 r/min时,不同间隙高度对单螺杆膨胀机内各泄漏通道泄漏量的影响.计算结果表明,当间隙高度相等时,各泄漏通道平均泄漏量从大到小依次为m8>m7>m2+4>m9>m6>m1(需要指出的是由壳体、星轮和螺杆围成的泄漏孔L3和L5,其对应的泄漏量较小,本文在间隙比较不同间隙值时,忽略泄漏量m3+5).主要的泄漏为螺杆与壳体之间的泄漏,这是由于膨胀过程中螺槽前后侧与壳体之间的泄漏线最长.若将螺杆与壳体之间的间隙高度减小20 μm,如图 4所示,各通道的平均泄漏量均有明显的降低.由于在实际的装配过程中,星轮齿与螺槽的啮合间隙相对于螺杆与壳体的配合间隙可以装配得更紧凑,因此,后续的研究所采用的泄漏通道间隙高度为星轮与螺槽之间的间隙值δ1=δ2+4=40 μm,星轮齿与壳体之间的间隙δ6 =50 μm,螺杆与壳体之间的间隙δ7=δ8=δ9=60 μm.

3.3 有机工质

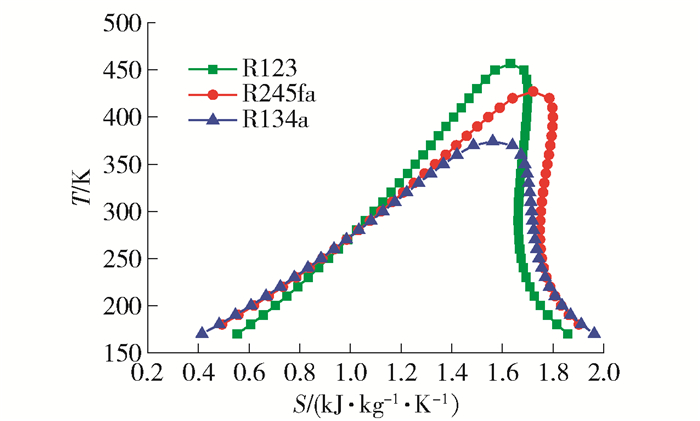

选择常见的3种有机工质R123、R134a、R245fa作为单螺杆膨胀机内的工质,工质的基本参数如表 2所示,由工质在T-S图(如图 5所示)的饱和汽化线可知,R134a为湿流体,R123和R245fa为干流体.

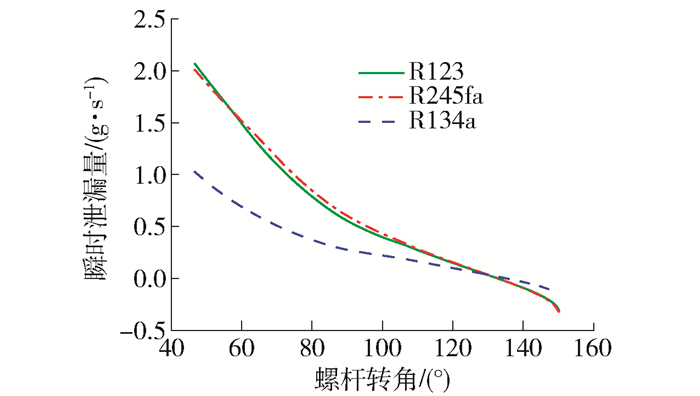

表 2 有机工质的基本参数Table 2. Basic parameters of organic fluids参数 R123 R245fa R134a 临界温度/℃ 183.68 154.01 101.10 临界压力/MPa 3.66 3.65 4.07 沸点/℃ 27.85 15.30 -26.10 臭氧消耗潜值 0.02 0.00 0.00 全球变暖潜值 93 820 1 300 安全性 B1 B1 A1 图 6给出了单螺杆膨胀机在进气压力为0.6 MPa、温度为373 K、转速为3 000 r/min时,在膨胀过程中基元容积内3种有机工质的瞬时泄漏量随着螺杆转角的变化关系.可以看出,在同一螺杆转角下,R123和R245fa的瞬时泄漏量的数值相差不大,在转角在40~130°时,R123和R245fa的瞬时泄漏量均大于R134a的泄漏量;在膨胀接近终了时,即转角在130~150°时,R134a的瞬时泄漏量高于R123和R245fa.这是由于相同的进气状态下,R123和R245fa的密度大于R134a的,使得泄漏的质量流量也高于后者.而膨胀接近终了时,由于R134a为湿流体,两相流态使得其泄漏质量流量高于干流体R123和R245fa的.

3.4 转速

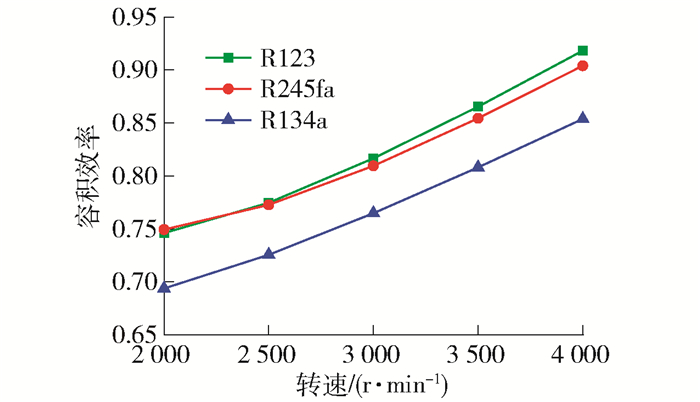

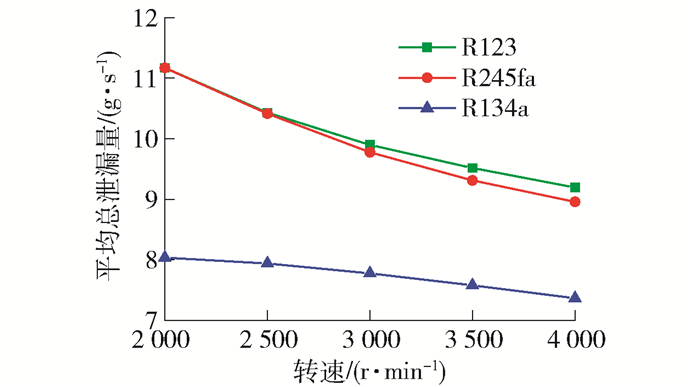

单螺杆膨胀机在进气压力为0.6 MPa、温度为373 K、转速在2 000~4 000 r/min变化时,3种不同有机工质R123、R134a、R245fa的单螺杆膨胀机的容积效率随转速的变化关系如图 7所示.从图中可以看出,随着转速的不断增加,各工质单螺杆膨胀机的容积效率均呈现递增的趋势,前半段增长缓慢,后半段快速增长.随着转速快速地增加,单螺杆膨胀机的理论排气量也相应地增大,同时泄漏量减小(如图 8所示),且转速较高时,泄漏量占总排气量的比重也减少,因而,容积效率不断增大.相同进气温度和进气压力的条件下,由于不同工质的密度和黏度均有所不同,因此,理论排气量和泄漏质量流量也不同.

在相同进气参数下,有机工质的密度由大到小依次为R123、R245fa、R134a,有机工质的黏度由小到大依次为R245fa、R123、R134a.在相同进气参数下,有机工质R134a的密度最小,黏度最大,故其泄漏量最小,使得膨胀终了基元容积内的质量较大,实际排气质量流量就较大.与R123和R245fa相比,R134a密度最小,理论质量排气流量最小,二者综合作用使得容积效率最低.因此,高转速下R123的容积效率高于R245fa的,R134a的容积效率最低.实际工况中,通过提高转速可以提高膨胀机的效率,但是,由于转速增大后,摩擦功率也会增加,螺杆的受力状况会较之低转速时加剧,轴承的磨损也会加剧.

3.5 进气压力

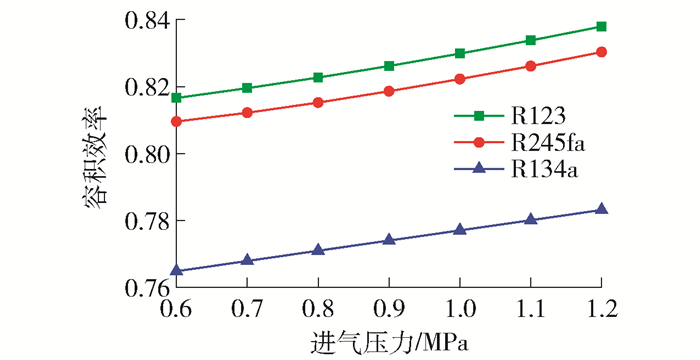

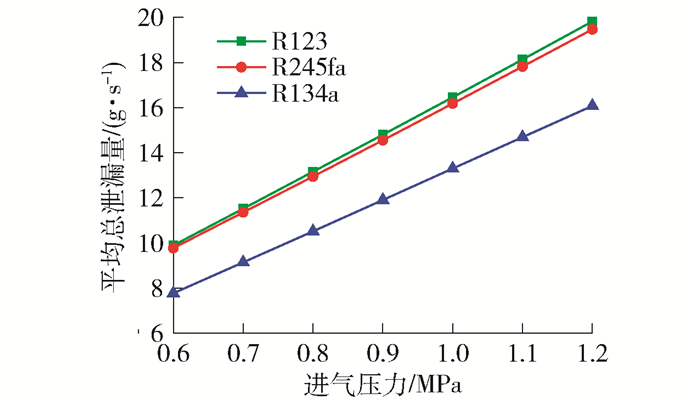

图 9和图 10所示为3种不同有机工质R123、R134a、R245fa的单螺杆膨胀机的容积效率和泄漏量分别随进气压力的变化关系,膨胀机的进气压力变化范围为0.6~1.2 MPa.可以看出,随着进气压力的升高, 单螺杆膨胀机的容积效率呈现直线上升的趋势.这是由于随着进气压力的增加,导致基元容积内压力增加,排气压力会增大,泄漏量也逐渐增大,进气压力增加的同时,使得进气工质的密度增加,因此,理论排气量也相应增大,但是相对于内泄漏量的增量,理论排气量增加较小,故二者作用后,容积效率随着进气压力的增加缓慢增大.同一进气压力下,容积效率和泄漏量由大到小依次为R123、R245fa、R134a,这是由于工质的密度和黏度的不同而引起的,密度越大,理论排气量和泄漏量越大,黏度越大,泄漏量越小,二者共同作用使得容积效率越大.比较3种有机工质,R123的容积效率最高.

4. 结论

通过质量和能量守恒原理建立单螺杆膨胀机热力学工作过程的数学模型和油气混合物的两相流泄漏模型,采用四阶龙格库塔法,并通过MATLAB软件求解该模型.

1) 9条泄漏通道中,螺杆与壳体之间的泄漏量占主要部分,其次是星轮与螺槽之间的泄漏量,星轮与壳体之间的泄漏量较小.当间隙高度相等时,各泄漏通道的平均泄漏量从大到小依次为m8>m7>m2+m4>m9>m6>m1.

2) 提高转速和进气压力均可以提高单螺杆膨胀机的容积效率, 且在单螺杆膨胀机中,干工质比湿工质的容积利用效率更高.其中,高转速下,以R123为工质的单螺杆膨胀机容积利用率最高,其次是R245fa, R134a最低.

-

表 1 单螺杆膨胀机基本结构参数

Table 1 Basic structural parameters of single screw expander

参数 数值 螺杆直径/mm 117 星轮直径/mm 117 中心矩/mm 93.6 星轮齿宽/mm 17.1 进气角/(°) 28.7 进气容积/dm3 0.010 2 内容积比 4.85 表 2 有机工质的基本参数

Table 2 Basic parameters of organic fluids

参数 R123 R245fa R134a 临界温度/℃ 183.68 154.01 101.10 临界压力/MPa 3.66 3.65 4.07 沸点/℃ 27.85 15.30 -26.10 臭氧消耗潜值 0.02 0.00 0.00 全球变暖潜值 93 820 1 300 安全性 B1 B1 A1 -

[1] YARI M. Exergetic analysis of various types of geothermal power plants[J]. Renewable Energy, 2010, 35:112-121. doi: 10.1016/j.renene.2009.07.023

[2] BORSUKIEWICZ-GOZDUR A. Dual-fluid-hybrid power plant co-powered by low-temperature geothermal water[J]. Geothermics, 2010, 39:170-176. doi: 10.1016/j.geothermics.2009.10.004

[3] 顾伟, 翁一武, 曹广益, 等.低温热能发电的研究现状和发展趋势[J].热能动力工程, 2007, 22(2):115-119. doi: 10.3969/j.issn.1001-2060.2007.02.001 GU W, WENG Y W, CAO G Y, et al. Research status and development trend of low-temperature thermal power[J]. Journal of Engineering for Thermal Energy and Power, 2007, 22(2):115-119. (in Chinese) doi: 10.3969/j.issn.1001-2060.2007.02.001

[4] 刘林顶.单螺杆膨胀机及其有机朗肯循环系统研究[D].北京: 北京工业大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10005-2010107986.htm LIU L D. Research on the single screw expander and organic Rankine cycle system[D]. Beijing: Beijing University of Technology, 2010. (in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10005-2010107986.htm

[5] GUSEV S, ZIVIANI D, BELL I H, et al. Experimental comparison of working fluids for organic rankine cycle with single-screw expander[C]//15th International Refrigeration and Air Conditioning Conference at Purdue. West Lafayette: Purdue University, 2014: 1-10.

[6] ZIVIANI D, BELL I H, BROEK M V D, et al. Comprehensive model of a single screw expander for ORC-systems[C]//22nd International Compressor Engineering Conference at Purdue. West Lafayette: Purdue University, 2014: 1-10.

[7] DESIDERI A, MARTIJN V D B, GUSEV S, et al. Experimental campaign and modeling of a low-capacity waste heat recovery system based on a single screw expander[C]//22nd International Compressor Engineering Conference at Purdue. West Lafayette: Purdue University, 2014: 1-10.

[8] WANG W, WU Y T, MA C F, et al. Experimental study on the performance of single screw expanders by gap adjustment[J]. Energy, 2013, 62:379-384. doi: 10.1016/j.energy.2013.09.031

[9] HE W, WU Y T, PENG Y H, et al. Influence of intake pressure on the performance of single screw expander working with compressed air[J]. Applied Thermal Engineering, 2013, 51:662-669. doi: 10.1016/j.applthermaleng.2012.10.013

[10] LU Y W, HE W, WU Y T, et al. Performance study on compressed air refrigeration system based on single screw expander[J]. Energy, 2013, 55:762-768. doi: 10.1016/j.energy.2013.03.051

[11] WANG W, WU Y T, MA C F, et al. Preliminary experimental study of single screw expander prototype[J]. Applied Thermal Engineering, 2011, 31:3684-3688. doi: 10.1016/j.applthermaleng.2011.01.019

[12] 刘一荻.单螺杆膨胀机输出扭矩的理论分析及其性能指标的研究探索[D].北京: 北京工业大学, 2015. LIU Y D. Theoretical study on output torque of single screw expander and analysis of performance evaluation parameters[D]. Beijing: Beijing University of Technology, 2015. (in Chinese)

[13] 张业强.基于单螺杆膨胀机的有机朗肯循环系统性能研究[D].北京: 北京工业大学, 2015. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2960921 ZHANG Y Q. Study on the performance of ORC system with a single-screw expander[D]. Beijing: Beijing University of Technology, 2015. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2960921

[14] 李国强, 吴玉庭, 赵英昆, 等.高压单螺杆膨胀机初步性能试验[J].北京工业大学学报, 2018, 44(6):926-932. http://www.bjutxuebao.com/bjgydx/CN/abstract/abstract5932.shtml LI G Q, WU Y T, ZHAO Y K, et al. Preliminary performance study of high pressure single screw expander[J]. Journal of University of Technology, 2018, 44(6):926-932. (in Chinese) http://www.bjutxuebao.com/bjgydx/CN/abstract/abstract5932.shtml

[15] BEIN T W, HAMILTON J F. Computer modeling of an oil flooded single screw air compressor[C]//Proceedings of Purdue Compressor Technology Conference at Purdue. West Lafayette: Purdue University, 1982: 127-134.

[16] BOBLITT W W, MOORE J. Computer modeling of single-screw oil-flooded refrigerant compressor[C]//International Compressor Engineering Conference at Purdue. West Lafayette: Purdue University, 1984: 550-56.

[17] 金光熹, 林强.单螺杆压缩机的泄漏通道和泄漏量计算[J].流体工程, 1986(1):19-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000002156378 JIN G X, LIN Q. Calculation of leakage path and leakage rate in single screw compressor[J]. Fluids Engineering, 1986(1):19-24. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000002156378

[18] 李红旗, 金光熹, 吴业正.喷油单螺杆压缩机的泄漏分析与计算[J].流体工程, 1993(8):14-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000004345703 LI H Q, JIN G X, WU Y Z. Analysis and calculation of leakage in oil-injected single screw compressor[J]. Fluids Engineering, 1993(8):14-18. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000004345703

[19] 吴建华, 金光熹, 束鹏程.单螺杆压缩机内部泄漏及其对性能影响的研究[J].西安交通大学学报, 1996, 30(4):66-71. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600556431 WU J H, JIN G X, SHU P C. Investigation of internal leakage in a single screw compressor and its influence on the performance[J]. Journal of Xi'an Jiaotong University, 1996, 30(4):66-71. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600556431

[20] WANG Z L, LIU Z, WU W F, et al. Research of leakage characteristics of single screw refrigeration compressors with the multicolumn envelope meshing pair[J]. International Journal of Refrigeration, 2015(49):1-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0234351568

[21] 熊则男, 乔宗亮.回转式压缩机与泵——共轭件啮合动态测试[M].北京:机械工业出版社, 1995. [22] 沈丽丽, 王伟, 吴玉庭.单螺杆膨胀机泄漏通道长度变化规律的理论分析[J].机械工程学报, 2015, 51(24):126-131. http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201524017 SHEN L L, WANG W, WU Y T. Theoretical analysis of variation of leakage path in single screw expander[J]. Journal of Mechanical Engineering, 2015, 51(24):126-131. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201524017

[23] 邢子文, 彭学院, 束鹏程. R134a螺杆制冷压缩机的泄漏特性研究[J].制冷学报, 2000(4):23-28. doi: 10.3969/j.issn.0253-4339.2000.04.006 XING Z W, PENG X Y, SHU P C. Study of leakage characteristics in twin screw compressor with refrigerant R134a[J]. Journal of Refrigeration, 2000(4):23-28. (in Chinese) doi: 10.3969/j.issn.0253-4339.2000.04.006

[24] LEI B, WANG W, WU Y T, et al. Development and experimental study on a single screw expander integrated into an Organic Rankine Cycle[J]. Energy, 2016, 116:43-52. doi: 10.1016/j.energy.2016.09.089

-

期刊类型引用(2)

1. 聂涛,周宏洋,邵华,王增丽. 地热能全流发电用两相单螺杆膨胀机理论膨胀过程热力特性研究. 西安交通大学学报. 2024(05): 190-199 .  百度学术

百度学术

2. 刘献飞,王恒,王方,李志强,朱彩霞,张浩飞. 单螺杆膨胀机螺旋槽道内液膜分布均匀特性. 化工学报. 2021(S1): 336-341 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: