Effect of Mix Proportion on the Properties of Phosphate-based Rapid Repairing Material With Desulfurized Fly-ash

-

摘要:

为解决混凝土结构快速修复及脱硫粉煤灰的资源化利用,提出利用脱硫粉煤灰、凝灰岩机制砂制备磷酸盐快速修复材料(MKPC).采用单因素试验方法研究了30℃高温下配合比参数对流动性、凝结时间和力学性能的影响,结合功效系数法确定满足多项指标的优化配合比参数.试验结果表明:MKPC流动度随着碱酸比、硼砂用量、水胶比、砂胶比及脱硫灰掺量的增大,依次呈抛物线型增加、指数衰减、线性增加、指数增长及指数衰减的变化规律;凝结时间随着碱酸比的增加呈线性递减变化,随硼砂用量、水胶比及脱硫灰掺量的增加呈指数增长型变化规律;1 h力学性能随着脱硫灰掺量的增加呈线性递减变化,随硼砂用量、水胶比及脱硫灰掺量的增加呈抛物线型变化规律.优化出的MKPC体系配合比参数满足快速修复现场施工要求.

Abstract:Phosphate cementitous material was considered as ideal rapid repairing materials owing to its excellent properties. However, its application was limited due to its shorter setting time and high cost. Phosphate-based rapid repairing material (MKPC) was prepared with desulfurization fly ash and tuff machine-made sand. Meanwhile the method of single-factor experimental design was adopted to study the effect of mix proportion on the properties of MKPC under high temperature conditions (30℃). The optimized mix proportion was determined by using value coefficient. The results show that the fluidity of MKPC demonstrates the parabola changes with M/P ratio, exponential decay with B/MPF ratio, linear growth with W/MPF ratio, exponential growth with S/MPF ratio, and exponential decay with CFB/MPF ratio. Secondly, the setting time of MKPC decreases linearly with the ratio of M/P, and increases with the ratio of B/MPF, W/MPF and CFB/MPF according to an exponential growth model. Thirdly, the mechanical property of MKPC about an hour declines linearly with the ratio of M/P, and improves with the ratio of B/MPF, W/MPF and CFB/MPF according to a parabola model. Finally, the optimized mix proportion is determined by using value coefficient, which meets the control range of the construction operability and early mechanical properties.

-

混凝土仍是各类建筑物的最主要结构材料,由于混凝土是典型脆性材料,经受自然灾害作用时经常出现开裂甚至倒坍,给人民生命财产安全造成巨大威胁.在灾后的救援过程中,如何快速修补或恢复各类交通和基础设施对于减轻和降低灾害具有重要意义[1].采用传统的水泥基材料进行现场修复时,将导致较长时间中断构筑物的使用,不适用于构筑物的快速修复和抢险加固.近年来,一种新型超快硬磷酸盐胶凝材料,具有早强、超强黏结力,良好的耐久性、耐火性和微膨胀性,是一种理想的快速修复材料[2],但其生产成本高、凝结时间较短[3].

李中华等[4]通过实验研究认为磷酸盐快速修补材料的抗压强度随水胶比和酸碱比的增大而降低,随着龄期的增长,水胶比和酸碱比对磷酸盐水泥抗压强度的影响逐步显著;高小建等[5]通过实验得出当酸碱比为1:2时,磷酸盐胶凝材料(MPB)水泥的强度达到最高值,1 d抗压强度超过50 MPa,灰砂比MPB:S为1.0:1.5时,砂浆强度达到最大值,3 h抗压强度达到50 MPa,掺入调凝组分10%左右即可使MPB水泥凝结时间控制在15~30 min,在保持流动度不变情况下,掺粉煤灰并不降低MPB胶凝材料强度;黄义熊等[6]研究了粉煤灰对磷酸盐水泥的影响,其中提到掺入10%粉煤灰,流动度提高近20%,随着粉煤灰掺量的增大,磷酸盐水泥的体积稳定性提高;汪宏涛等[7]提出酸碱比对凝结时间影响较小,对强度的影响则比较显著,当酸碱比为1:4时,修补材料强度取得最大值,2 h抗压强度达35 MPa以上,随着缓凝剂掺量的增大,新型磷酸盐水泥修补材料的凝结时间逐渐延长,而强度则随之降低;金城等[8]通过实验得出粉煤灰对材料的强度有一定降低,但能提高其流动度,且降低后的3 h强度也高达32.9 MPa;Ding等[9]则认为在MPC中掺入40%粉煤灰,其早期强度、后期强度均显著提高.

此外,随着循环流化床锅炉及其脱硫技术的推广使用,产生了大量的脱硫粉煤灰.脱硫粉煤灰是普通粉煤灰、脱硫产物、未反应完全的脱硫剂的混合物,其SO3含量较高,不宜用作水泥及混凝土掺合料,大多采用填埋处理.与硅酸盐水泥基材料相比,磷酸盐胶凝材料对原材料的要求较低,因此考虑将脱硫粉煤灰用于磷酸盐快速修复材料的制备,以延长磷酸盐快速修复材料的凝结时间,降低生产成本,同时为脱硫粉煤灰资源化利用提供新思路.

上述研究中较少有研究脱硫粉煤灰在磷酸盐胶凝材料体系中的利用,同时现有的成果主要是在室温下获得的,但东部沿海夏天温度高于30 ℃情况频繁发生,因此,本文研究高温环境下配合比参数对脱硫灰磷酸盐快速修复材料的影响,探求各组分间最佳配合比,并为脱硫粉煤灰资源化利用提供新途径.

1. 原材料与试验方法

1.1 原材料

过烧氧化镁(MgO,简称M):由孙氏炉料耐火材料有限公司生产的重烧镁砂经球磨机研磨得到,粒径分布为大于0.16 mm的占2.9%,0.08~0.16 mm的占37.2%,小于0.08 mm的占59.9%.其化学成分见表 1.

表 1 过烧氧化镁、CFB脱硫粉煤灰的化学分析Table 1. Chemical analysis of dead burnt magnesia and CFB fly-ash% 原材料 w(SiO2) w(Al2O3) w(Fe2O3) w(CaO) w(MgO) w(Na2O) w(K2O) w(SO3) w(f-CaO) w(Loss) 过烧氧化镁 0.62 0.32 0.86 2.38 93.23 0.03 — 0.62 — 0.33 CFB脱硫灰 52.14 21.80 3.63 14.68 0.78 0.32 1.32 2.26 6.29 1.02 磷酸二氢钾(KH2PO4,简称P):宁波鄞州朝阳圣达化工厂所提供的工业级,KH2PO4质量分数≥98%,径粒为120~180 μm,溶解度226 g/L(20 ℃).

机制砂(简称S):象山磊顺石料有限公司的凝灰岩机制砂,细度模数为3.0,石粉质量分数8%.

硼砂(Na2B4O7·10H2O,简称B):无锡市建业试剂化工公司提供的分析纯.

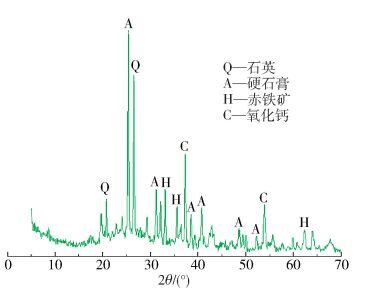

脱硫粉煤灰(简称CFB):宁波长丰热电厂所提供的钙基脱硫副产物,需水比106,SO3质量分数2.26%,烧失量10.2%.其化学成分与矿物组成如表 1、图 1所示,粒度分布如表 2所示.

表 2 CFB脱硫灰的粒度分析Table 2. Particle size analysis of the CFB fly-ashD10/μm D50/μm D90/μm 0~45μm/% 0.86 4.18 13.05 99.15 注:D10、D50、D90分别为样品的累计粒度质量分数分别达到10%、50%、90%时对应的粒径. 1.2 试验方法

由于MKPC材料设计中,其关键参数为m(M)/m(P)(碱酸比)、m(B)/m(MPF)(硼砂用量)、m(W)/m(MPF)(水胶比)、m(S)/m(MPF)(砂胶比)及m(CFB)/m(MPF)(脱硫灰掺量),其中MPF为M、P、CFB的总和,因此试验通过改变各参数的值,以研究磷酸盐胶凝材料的施工性能、早期力学性能随参数的变化规律,试验共设计了23组,基准配合比参数如表 3所示.

表 3 配合比参数Table 3. Mix-designed parameters项目 m(M)/

m(P)m(B)/

m(MPF)m(W)/

m(MPF)m(S)/

m(MPF)m(CFB)/

m(MPF)配合比 2 6% 0.16 0.5 10% 各原材料在30 ℃恒温环境下放置24 h,然后按照配合比参数配制,加水搅拌3 min后快速成型进行凝结时间、流动度及力学性测试.其中流动度测试参考《水泥胶砂流动度测定方法》(GB/T2419—2005) 进行;初凝凝结时间测定依据《水泥标准稠度用水量、凝结时间、安定性检验办法》(GB/T 1346—2011) 中有关办法进行;抗压强度、抗折强度测试按照《水泥胶砂强度检验方法》(GB/T17671—2005) 进行.

2. 试验结果与分析

2.1 流动度

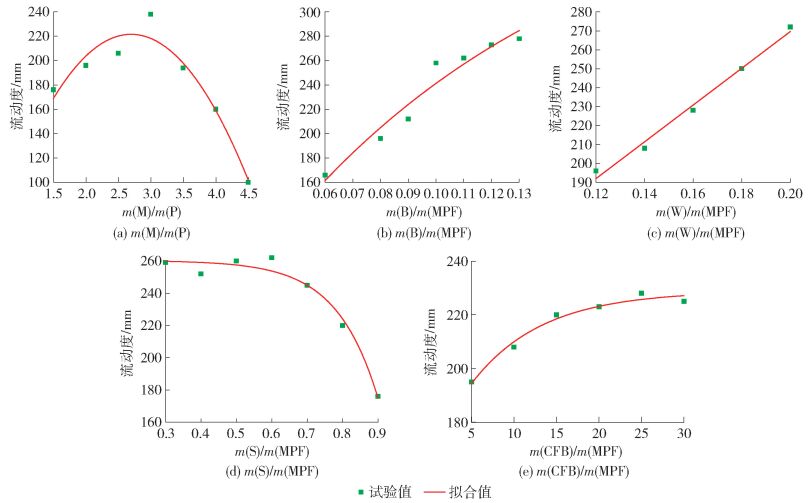

图 2为脱硫灰磷酸盐快速修复材料(简称MKPC)中不同碱酸比、硼砂用量、水胶比、砂胶比及脱硫粉煤灰掺量在30 ℃高温下对其浆体流动性的影响试验结果,上述因素对流动度影响程度依次为m(M)/m(P)>m(B)/m(MPF)>m(W)/m(MPF)>m(S)/m(MPF)>m(CFB)/m(MPF).

从图 2中还可以看出,流动度随着碱酸比的增大表现为先增加后减小,在碱酸比为3.0时取得最大流动度238 mm,相比1.5时流动度增加了37%,统计资料表明两者呈抛物线型变化(流动度y=-36.76x2+198.29x-45.81,相关系数R2=0.904).其原因为MgO的增加一方面可改善MKPC组分间的级配和孔隙结构,减少机制砂之间的摩擦力,改善流动性;但另一方面又使体系总比表面积增加,需要润湿水分增多,同时电离出的Mg2+增多,反应速率加快,体系温度升高,在用水量相同情况下浆体流动性降低.所以在用水量不变下碱酸比对流动度存在合理比值.

MKPC浆体的流动度随硼砂用量增多而增大,硼砂用量从8%增加到10%时,流动度增长了35.4%,但硼砂用量从10%增加到13%时,流动度仅增长了7.7%,根据统计数据回归两者呈指数衰减型变化规律(流动度y=-451.35exp(-0.092x)+422.22,相关系数R2=0.921).其原因为硼砂与氧化镁发生络合,在氧化镁颗粒表面形成一层保护膜,阻碍了水化反应,减少了因水化反应及温度蒸发而损失的水量,表现出机制砂表面吸附的浆体膜层厚度增加,流动度改善,但集料对浆体的物理吸附膜层达到一定厚度,形成一定的饱和度,此时继续增大硼砂掺量,将出现流浆或泌水现象,流动度改善作用不再那么显著.

随水胶比的增大,MKPC浆体的流动度逐渐改善,水胶比从0.12增加到0.20时,流动度从196 mm增加到272 mm,提高了38.8%,统计分析两者呈线性正相关性(流动度y=970x+75.6,相关系数R2=0.986).水胶比在一定范围内,水胶比增大,则机制砂吸附的浆体膜层越厚,摩擦力越小,因此流动性越好.

砂胶比对流动性的影响呈指数增长型变化规律(流动度y=-0.04exp(8.33x)+260.26,相关系数R2=0.964),小于0.6时,砂胶比对流动度的影响不明显,大于0.6后,其流动度下降速度增大,砂胶比从0.3增大到0.9时,流动度从259 mm下降到176 mm,降低幅度32%.主要在于砂胶比较小时,浆体包裹砂粒的效果强,随着砂胶比的增大,砂粒外包裹的浆体膜逐渐变薄,摩阻力增大,造成流动性下降.

脱硫粉煤灰取代胶凝材料可改善MKPC流动性,脱硫灰掺量从10%增长到25%,流动度由208 mm增加到228 mm,提高9.6%,两者之间呈指数衰减型变化规律(流动度y=-62.8exp(-0.12x)+228.85,相关系数R2=0.966).

MKPC体系水化反应主要是酸碱中和反应,即:MKPC加水后,磷酸二氢钾快速溶于水,使溶液呈酸性,氧化镁颗粒溶解于酸性溶液中,并电离Mg2+,Mg2+与磷酸根、水反应生成MgKPO4·6H2O(MKP),随着反应进行,包裹在MgO颗粒表面的水化物MKP相互接触形成以未反应MgO颗粒为核心,MKP在其周围相互搭接的网络结构,使MKPC浆体凝结硬化;同时MKPC水化体系中MgO的溶解速度与体系的反应温度、液相pH值有关,体系反应温度越高、液相pH值越低,MgO溶解速度越快,水化反应加快[11],粉煤灰还具有吸附磷酸根的作用, 这种效应可延缓MKPC的凝结硬化过程[12].相同用量下,脱硫粉煤灰的掺入降低了酸碱组分用量,使得体系水化温度降低,因此脱硫粉煤灰通过降低体系水化温度、吸附磷酸根,达到延缓水化,流动度改善的作用,另一方面脱硫粉煤灰具有玻璃相含量较低、颗粒形状多不规则、多孔、结构疏松、烧失量高的特性[13], 使CFB需水比大.

2.2 凝结时间

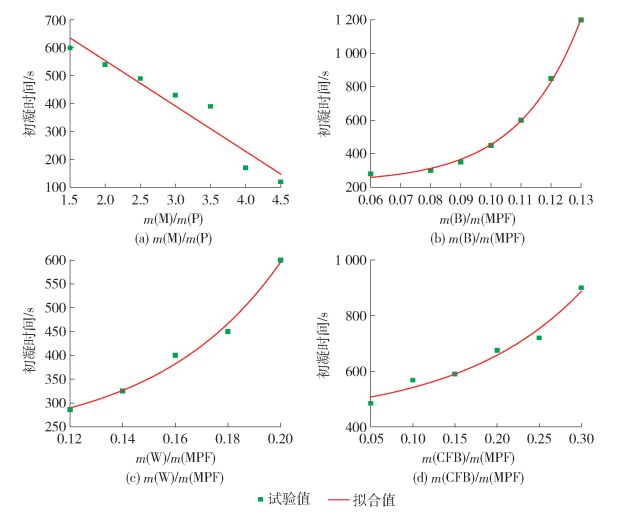

图 3为不同碱酸比、硼砂用量、水胶比及脱硫粉煤灰掺量的MKPC在30 ℃高温下的凝结时间,上述因素对凝结时间影响程度依次为m(B)/m(MPF)>m(M)/m(P)>m(CFB)/m(MPF)>m(W)/m(MPF).

从图 3中可以发现,随着m(M)/m(P)的增加,MKPC快速修复材料凝结时间逐渐减小,m(M)/m(P)从1.5增加到4.5时,凝结时间从600 s减少到125 s,下降了79%,统计分析表明两者呈线性递减关系(凝结时间y=880-162.86x,相关系数R2=0.964).其原因为MKPC体系水化反应其实是氧化镁与磷酸二氢钾溶液之间的酸碱反应,又因磷酸二氢钾易溶于水,因此水化反应速率主要由氧化镁的溶解速率控制,m(M)/m(P)值越大,则氧化镁相对含量越对,溶解量也相应增加,水化产物的量越多,其凝聚结构的形成越早,初凝现象出现的越早.

m(B)/m(MPF)对凝结时间的影响呈指数增长型变化规律(凝结时间y=1.78exp(0.49x)+225.77,相关系数R2=0.997),在30 ℃高温下m(B)/m(MPF)小于10%时,其改善幅度不大,大于10%后其缓凝效果明显.硼砂的缓凝作用是通过降低MPC浆体的反应温度及在氧化镁颗粒表面形成一层保护膜.但硼砂掺量比较低时,硼砂不足以包裹在MgO表面,溶液中OH-和Mg2+浓度开始迅速提高,MPC体系溶液中快速发生酸碱反应,伴随大量放热,又进一步促进MPC体系温度升高,因而当硼砂用量大于10%时,其缓凝作用显著.

凝结时间随着m(W)/m(MPF)的增大而延长,m(W)/m(MPF)从0.12增大到0.20,凝结时间从5 min延长到10 min,统计分析表明两者呈指数增长型关系(凝结时间y=5.74exp(20.92x)+219.29,相关系数R2=0.979). m(W)/m(MPF)大意味着达到过饱和溶液时间长、颗粒之间距离大,形成相互搭接连生的凝聚结构需要更多的水化产物,因此凝结时间也延长.

脱硫粉煤灰用量对凝结时间影响呈指数递增变化规律(凝结时间y=60.24exp(0.07x)+422.7,相关系数R2=0.956),m(CFB)/m(MPF)从5%增加到30%时,凝结时间从8 min延长到15 min,但m(CFB)/m(MPF)大于15%后缓凝效果明显.这是由于脱硫粉煤灰具有较高pH值[14],可抑制MKPC体系中MgO的溶解,脱硫灰多孔、结构疏松与烧失量高的特性对磷酸根离子具有吸附效应,同时掺入脱硫灰降低体系反应温度,从而延缓水化.

2.3 力学性能

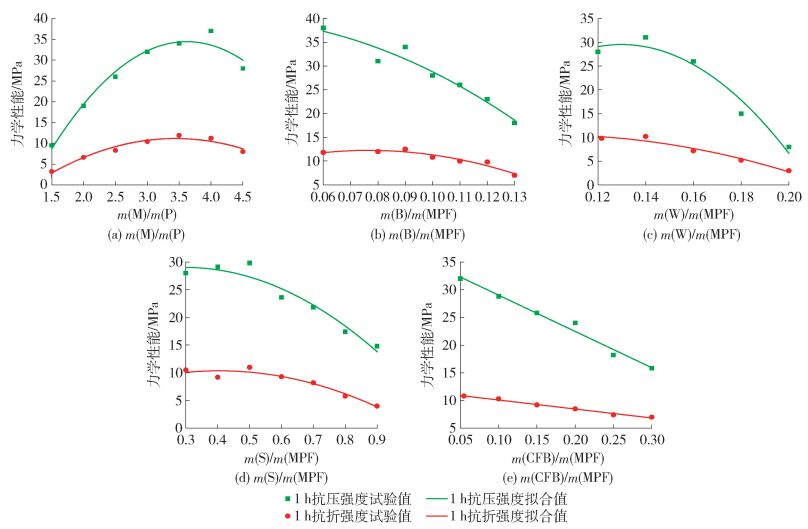

图 4为不同碱酸比、硼砂用量、水胶比、砂胶比及脱硫粉煤灰掺量的MKPC在30 ℃高温下静置1 h的抗压强度和抗折强度,上述因素对1 h力学性能影响程度依次为m(M)/m(P)>m(W)/m(MPF)>m(B)/m(MPF)>m(CFB)/m(MPF)>m(S)/m(MPF).

从图中还可以看出MKPC体系1 h力学性能随m(M)/m(P)的变化呈抛物线型增长趋势(抗压强度y=-5.74x2+41.54x-40.73,相关系数R2=0.950;抗折强度y=-2.2x2+15.14x-14.91,相关系数R2=0.928),存在临界值,m(M)/m(P)约为3.5时具有最大抗压强度、抗折强度.当m(M)/m(P)小于临界值3.5时,抗压强度、抗折强度随碱酸比的增大而提高,随后随碱酸比的增大而减小.其原因为MKPC体系水化是氧化镁与磷酸二氢钾溶液的酸碱反应,形成水化产物KMgPO4·6H2O,以机制砂、未反应完全的氧化镁及粉煤灰等散粒状材料为骨架,以KMgPO4·6H2O为黏结相,形成空间网络结构,其强度大小与空间网络结构的完整度、密实性相关.当m(M)/m(P)小于临界值时,酸碱反应中氧化镁不足,氧化镁随着m(M)/m(P)值增加而增加,水化产物生成量相应增多,当达到临界值后,进一步增大m(M)/m(P)值时,磷酸二氢钾又显得不足,使得水化物生成量反而减少.因此m(M)/m(P)值处于临界值时,生成的水化产物最多,网络结构完整度、密实性更好,强度最大.

m(B)/m(MPF)对MKPC的1 h力学性能的影响呈抛物型变化趋势(抗压强度y=-0.18x2+0.75x+39.29,相关系数R2=0.912;抗折强度y=-0.17x2+2.64x+2.13,相关系数R2=0.895),存在临界值,m(B)/m(MPF)为2%左右时,抗压强度值最大,m(B)/m(MPF)为8%左右抗折强度最大.硼砂掺入后具有一定的缓凝作用,一方面可以减少体系温度蒸发水量及水化反应消耗的水分,延长凝结时间、改善流动度,使MKPC材料内部致密性增强,一定程度上改善力学性能;另一方面,硼砂可以抑制MgO颗粒溶解,水化产物的早期生成量与晶体形态发生改变,晶体粗大、堆积松散,同时硼砂晶体表面光滑且强度低,与胶凝材料的黏结力很小,成为薄弱区[15],因此MKPC体系中未溶解的硼砂粒子会降低早期强度.因此共同左右下,硼砂用量较小时可以提高体系强度,继续增大将降低强度.

m(W)/m(MPF)对MKPC力学性能的影响也具有抛物型变化规律(抗压强度y=-4 642.9x2+1 205.7x-48.74,相关系数R2=0.919;抗折强度y=-750x2+147x+3.36,相关系数R2=0.921),抗压、抗折强度对应的临界m(W)/m(MPF)依次约为0.13、0.10. m(W)/m(MPF)临界值内,增大m(W)/m(MPF)可改善施工性能,使硬化体结构更加密实,材料的强度提高,但m(W)/m(MPF)进一步增大时,空隙结构增大,强度开始迅速下降.

m(S)/m(MPF)对MKPC力学性能的影响也具有抛物型变化规律(抗压强度y=-41.9x2+24.93x+25.3,相关系数R2=0.911,抗折强度y=-26.54x2+21.46x+6.02,相关系数R2=0.902),抗压、抗折强度对应的临界m(S)/m(MPF)依次约为0.3、0.4.在m(S)/m(MPF)临界值内,机制砂在水化产物中起骨架作用,在浆体富余下,其早期力学性能随着m(S)/m(MPF)的增加而增加,但继续增大m(S)/m(MPF)时,使得机制砂包裹的浆体层厚度不够,流动性下降,试件成型不易振捣密实,同时m(S)/m(MPF)增大,导致水化产物数量显得不足,影响了水化空间网络结构的完整度、密实性,使得抗压强度、抗折强度呈现迅速下降的趋势.

脱硫粉煤灰与1 h力学性能呈线性递减的关系(抗压强度y=-0.16x+11.71,相关系数R2=0.984;抗折强度y=-0.65x+35.56,相关系数R2=0.977),其原因是脱硫灰取代胶凝材料对MKPC而言反应物减少了,导致水化物数量不足,影响到水化产物与未水化的氧化镁颗粒间形成的水化空间网络结构,使1 h力学性能降低.虽然脱硫灰具有填充效应,但是对早期力学性能主要贡献取决于水化产物数量.因此随着脱硫灰的掺入,MKPC体系1 h力学性能下降.

2.4 配合比参数优化

功效系数法是E.C.Harrington在1965年提出的一种多目标优化问题的求解方法,其方法[16]为:设计试验考核n个指标,每一个指标的功效系数为di(0≤di≤1),则总功效系数为

$$d = {\left( {{d_1} \times {d_2} \times {d_3} \cdots \times {d_n}} \right)^{1/n}}$$ 式中:系数di表示第i个考核指标实现的满意程度;d表示n个指标的总的优劣情况. di的确定方法为用di=1表示第i个指标的效果最好,相应地对同列各指标的取值作为归一化处理,计算总功效系数.利用功效系数方法确定多目标下配合比设计参数是一种简单、有效的方法[16],本文结合快速修复材料的性能要求,主要选取流动度、凝结时间、抗折强度、抗压强度作为考核指标,计算出各配合比参数在不同数值下的总功效系数,结果见表 4所示. MKPC体系中配合比参数中最大总功效系数对应的参数为其最优值(见表 4中粗体).考虑到m(CFB)/m(MPF)在10%~20%,其总功效系数相差不大,结合成本问题与利废率,选择m(CFB)/m(MPF)=20%,因此MKPC体系最优配合比参数为m(M)/m(P)=3、m(B)/m(MPF)=12%、m(W)/m(MPF)=0.14、m(S)/m(MPF)=0.5及m(CFB)/m(MPF)=20%.

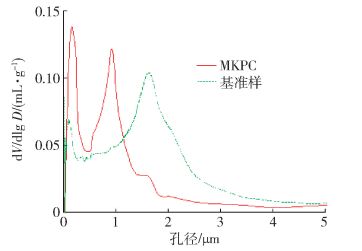

表 4 功效系数分析表Table 4. Analysis of value coefficient项目 m(M)/m(P) m(B)/m(MPF) m(S)/m(MPF) m(CFB)/m(MPF) m(W)/m(MPF) 1.5 2 2.5 3.0 3.5 4 4.5 0.06 0.08 0.09 0.10 0.11 0.12 0.13 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.05 0.10 0.15 0.20 0.25 0.30 0.12 0.14 0.16 0.18 0.2 总功效系数d 0.48 0.67 0.77 0.86 0.84 0.65 0.45 0.60 0.61 0.67 0.69 0.71 0.76 0.72 0.95 0.92 0.99 0.87 0.79 0.65 0.53 0.82 0.84 0.81 0.81 0.69 0.62 0.74 0.80 0.76 0.64 0.52 结合上述优化出的配合比参数成型试件,并以同配合比参数下Ⅱ级粉煤灰、河砂制备的磷酸盐快速修复材料为基准,进行凝结时间、流动度及力学性能对比分析,其结果见表 5.现场快速修复材料施工要求[5, 17],小面积修补通常要求初凝时间不早于15 min,稍大面积修补需要控制在20 min以上,1 h抗压强度应能达到20 MPa.根据此原则,优化出的配合比参数满足快速修复材料施工要求;同时与粉煤灰、河沙制备的磷酸盐快速修复材料相比,MKPC流动性略有下降、凝结时间略有缩短,1 h的抗压强度、抗折强度增加,表明脱硫灰与机制砂制备的磷酸盐修复材料具有更好的早期力学性能,其原因是脱硫粉煤灰氧化钙含量较高,CaO在酸性溶液中的溶解度较高[3],使得脱硫灰与酸性磷酸盐迅速反应,生成更多的水化产物填充在空隙中,使得MKPC的紧密程度相比基准样更致密,如图 5所示;此外机制砂的颗粒形貌较河砂粗糙,因而与基准样比,脱硫灰磷酸盐修复材料的流动性稍差些,凝结时间提前,早期力学性能较好.

表 5 MKPC性能测试结果Table 5. Performance test results of MKPC样品 流动度/mm 凝结时间/min 抗压强度/MPa 抗折强度/MPa 1 h 28 d 1 h 28 d MKPC 230 21 29.2 58.7 11.3 12.6 基准样 240 28 26.1 — 9.8 — 3. 结论

1) MKPC快速修复材料流动度随着m(M)/m(P)、m(B)/m(MPF)、m(W)/m(MPF)、m(S)/m(MPF)及m(CFB)/m(MPF)的增大,依次呈抛物线型、指数衰减型、线性正相关性、指数增长型及指数衰减型的变化,对流动度影响程度依次为m(M)/m(P)>m(B)/m(MPF)>m(W)/m(MPF)>m(S)/m(MPF)>m(CFB)/m(MPF).

2) MKPC快速修复材料凝结时间随着m(M)/m(P)的增加呈线性递减变化,随m(B)/m(MPF)、m(W)/m(MPF)及m(CFB)/m(MPF)的增加呈指数增长型变化;对凝结时间影响程度依次为m(B)/m(MPF)>m(M)/m(P)>m(CFB)/m(MPF)>m(W)/m(MPF).

3) MKPC快速修复材料1 h力学性能随着m(CFB)/m(MPF)的增加呈线性递减变化,随m(B)/m(MPF)、m(W)/m(MPF)及m(CFB)/m(MPF)的增加呈抛物线型变化;对1 h力学性能影响程度依次为m(M)/m(P)>m(W)/m(MPF)>m(B)/m(MPF)>m(CFB)/m(MPF)>m(S)/m(MPF).

4) 采用功效系数法获得MKPC体系凝结时间、流动度及力学性能多目标下最优配合比参数,即:m(M)/m(P)=3、m(B)/m(MPF)=12%、m(W)/m(MPF)=0.14、m(S)/m(MPF)=0.5及m(CFB)/m(MPF)=20%,满足快速修复现场施工要求.

-

表 1 过烧氧化镁、CFB脱硫粉煤灰的化学分析

Table 1 Chemical analysis of dead burnt magnesia and CFB fly-ash

% 原材料 w(SiO2) w(Al2O3) w(Fe2O3) w(CaO) w(MgO) w(Na2O) w(K2O) w(SO3) w(f-CaO) w(Loss) 过烧氧化镁 0.62 0.32 0.86 2.38 93.23 0.03 — 0.62 — 0.33 CFB脱硫灰 52.14 21.80 3.63 14.68 0.78 0.32 1.32 2.26 6.29 1.02 表 2 CFB脱硫灰的粒度分析

Table 2 Particle size analysis of the CFB fly-ash

D10/μm D50/μm D90/μm 0~45μm/% 0.86 4.18 13.05 99.15 注:D10、D50、D90分别为样品的累计粒度质量分数分别达到10%、50%、90%时对应的粒径. 表 3 配合比参数

Table 3 Mix-designed parameters

项目 m(M)/

m(P)m(B)/

m(MPF)m(W)/

m(MPF)m(S)/

m(MPF)m(CFB)/

m(MPF)配合比 2 6% 0.16 0.5 10% 表 4 功效系数分析表

Table 4 Analysis of value coefficient

项目 m(M)/m(P) m(B)/m(MPF) m(S)/m(MPF) m(CFB)/m(MPF) m(W)/m(MPF) 1.5 2 2.5 3.0 3.5 4 4.5 0.06 0.08 0.09 0.10 0.11 0.12 0.13 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.05 0.10 0.15 0.20 0.25 0.30 0.12 0.14 0.16 0.18 0.2 总功效系数d 0.48 0.67 0.77 0.86 0.84 0.65 0.45 0.60 0.61 0.67 0.69 0.71 0.76 0.72 0.95 0.92 0.99 0.87 0.79 0.65 0.53 0.82 0.84 0.81 0.81 0.69 0.62 0.74 0.80 0.76 0.64 0.52 表 5 MKPC性能测试结果

Table 5 Performance test results of MKPC

样品 流动度/mm 凝结时间/min 抗压强度/MPa 抗折强度/MPa 1 h 28 d 1 h 28 d MKPC 230 21 29.2 58.7 11.3 12.6 基准样 240 28 26.1 — 9.8 — -

[1] 司炳君, 孙治国, 杜修力, 等.钢筋混凝土桥墩地震弯剪破坏机理与震后快速修复技术研究[J].土木工程学报, 2011, 44(7):90-99 http://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201107015.htm SI B J, SUN Z G, DU X L, et al. Study on the seismic flexural-shear damage mechanisms and rapid repair techniques for earthquake damaged bridge piers[J]. China Civil Engineering Journal, 2011, 44(7):90-99. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201107015.htm

[2] YANG N, SHI C J. Research progresses in magnesium phosphate cement-based materials[J]. Journal of Materials in Civil Engineering, 2014, 26(10):1-8 https://trid.trb.org/view.aspx?id=1310426

[3] 陈兵, 吴震, 吴雪萍.磷酸镁水泥改性试验研究[J].武汉理工大学学报, 2011, 33(4):30-34 http://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201104008.htm CHEN B, WU Z, WU X P. Experimental research on the properties of modified MPC[J]. Journal of Wuhan University of Technology, 2011, 33(4):30-34. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-WHGY201104008.htm

[4] 李中华, 张佳良, 蒋亚清.磷酸盐快速修补材料性能研究[J].混凝土与水泥制品, 2011(8):8-11 http://www.cnki.com.cn/Article/CJFDTOTAL-HNTW201108002.htm LI Z H, ZHANG J L, JIANG Y Q. Study on the performance of rapid repair material phosphate[J]. Concrete and Cement Products, 2011(8):8-11. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-HNTW201108002.htm

[5] 高小建, 杨英姿, 邓红卫, 等.灾后混凝土工程快速修补材料的研究[J].四川大学学报(工程科学版), 2010, 42(2):40-45 http://www.cnki.com.cn/Article/CJFDTOTAL-SCLH201002010.htm GAO X J, YANG Y Z, DENG H W, et al. Research on rapid repairing material for concrete structures undergone natural disaster[J]. Journal of Sichuan University (Engineering Science Edition), 2010, 42(2):40-45. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-SCLH201002010.htm

[6] 黄义雄, 钱觉时, 王庆珍, 等.粉煤灰对磷酸盐水泥耐水性能的影响[J].材料导报, 2011(增刊1):470-473 http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2011S1136.htm HUANG Y X, QIAN J S, WANG Q Z, et al. Influence of fly ash on water resistance of magnesia phosphate cement[J]. Journal of Materials, 2011(Suppl 1):470-473. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2011S1136.htm

[7] 汪宏涛, 曹巨辉, 薛明, 等.新型超快硬磷酸盐水泥修补材料的研究[J].新型建筑材料, 2009, 36(7):49-51 http://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ200907025.htm WANG H T, CAO J H, XUE M, et al. Study on the new phosphate cement repair material with super rapid hardening[J]. New Building Materials, 2009, 36(7):49-51. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ200907025.htm

[8] 金城, 杨全兵.粉煤灰对磷酸盐快速修补材料性能的影响[J].粉煤灰综合利用, 2013(2):36-37 http://www.cnki.com.cn/Article/CJFDTOTAL-FMLE201302012.htm JIN C, YANG Q B. The influence of fly ash on properties of phosphate rapid repairing material[J]. Comprehensive Utilization of Fly Ash, 2013(2):36-37. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-FMLE201302012.htm

[9] DING Z, LI Z J. High stength phosphate cement with fly ash[J]. ACI Material Journal, 2005, 102(6):375-381.

[10] 夏锦红, 袁大伟, 王立久.磷酸镁水泥水化机理研究[J].武汉理工大学学报, 2009, 31(9):25-28 http://www.cnki.com.cn/Article/CJFDTOTAL-WHGY200909008.htm XIA J H, YUAN D W, WANG L J. Research on hydration mechanism of magnesia phosphate cement[J]. Journal of Wuhan University of Technology, 2009, 31(9):25-28. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-WHGY200909008.htm

[11] BURNS R T, MOODY L B. Phosphorus recovery from animal manures using optimized struvite precipitation[C]//Proceedings of coagulants and flocculants:global market and technicalopportunities for water treatment chemicals. Chicago:[s. n.], 2002:1-7.

[12] 林玮, 孙伟, 李宗津.磷酸镁水泥中的粉煤灰效应研究[J].建筑材料学报, 2010, 13(6):716-721 http://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201006007.htm LIN W, SUN W, LI Z J. Study on the effects of fly ash in magnesium phosphate cement[J]. Journal of Building Materials, 2010, 13(6):716-721. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JZCX201006007.htm

[13] BIGHAM J M, KOST D A, STEHOUWER R C, et al. Mineralogical and engineering characteristics of dry flue gas desulfurization products[J]. Fuel, 2005, 84:1839-1848. doi: 10.1016/j.fuel.2005.03.018

[14] 邵霞, 陆文雄.脱硫粉煤灰的综合利用及其资源化[J].洁净煤技术, 2009, 15(5):104-107 http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS200905038.htm SHAO X, LU W X. The utilization and resource regeneration of desulfurization fly ash[J]. Clean Coal Technology, 2009, 15(5):104-107. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS200905038.htm

[15] 薛明, 曹巨辉, 蒋江波, 等.硼砂对磷酸镁水泥性能影响及微观作用机理分析[J].后勤工程学院学报, 2011, 27(6):52-55 http://www.cnki.com.cn/Article/CJFDTOTAL-HQGC201106011.htm XUE M, CAO J H, JIANG J B, et al. Influence of borax on properties of magnesium phosphate cement and its microscopic mechanism[J]. Journal of Logistical Engineering University, 2011, 27(6):52-55. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-HQGC201106011.htm

[16] 姚武, 郑欣.配合比参数对混凝土热膨胀系数的影响[J].同济大学学报(自然科学版), 2007, 35(1):77-81, 87 http://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ200701015.htm YAO W, ZHENG X. Effect of mix proportion on coefficient of thermal expansion of concrete[J]. Journal of Tongji University (Natural Science), 2007, 35(1):77-81, 87. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ200701015.htm

[17] 王庆珍, 钱觉时, 秦继辉, 等.环境温度对磷酸镁水泥凝结时间和强度发展的影响[J].硅酸盐学报, 2013, 41(11):1493-1498 http://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201311006.htm WANG Q Z, QIAN J S, QIN J H, et al. Effect of ambient temperature on setting time and strength development of magnesia-phosphate cement[J]. Journal of the Chinese Ceramic Society, 2013, 41(11):1493-1498. (in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201311006.htm

下载:

下载: